Introduction to Modern Refrigeration Equipment

The refrigeration industry continues to evolve as businesses seek reliable and efficient cooling solutions for their operations. Among the various equipment options available, open type condensing units have gained significant attention in recent years. These systems play a crucial role in industrial and large commercial refrigeration applications, providing the necessary power to maintain optimal temperatures for cold storage, food processing, and cold chain logistics.

Understanding how these units work and what benefits they offer can help business owners make informed decisions when selecting refrigeration equipment. This article addresses some of the most common questions people have about open type condensing units, providing clear and straightforward information to help you evaluate whether this type of equipment suits your needs.

What Is an Open Type Condensing Unit?

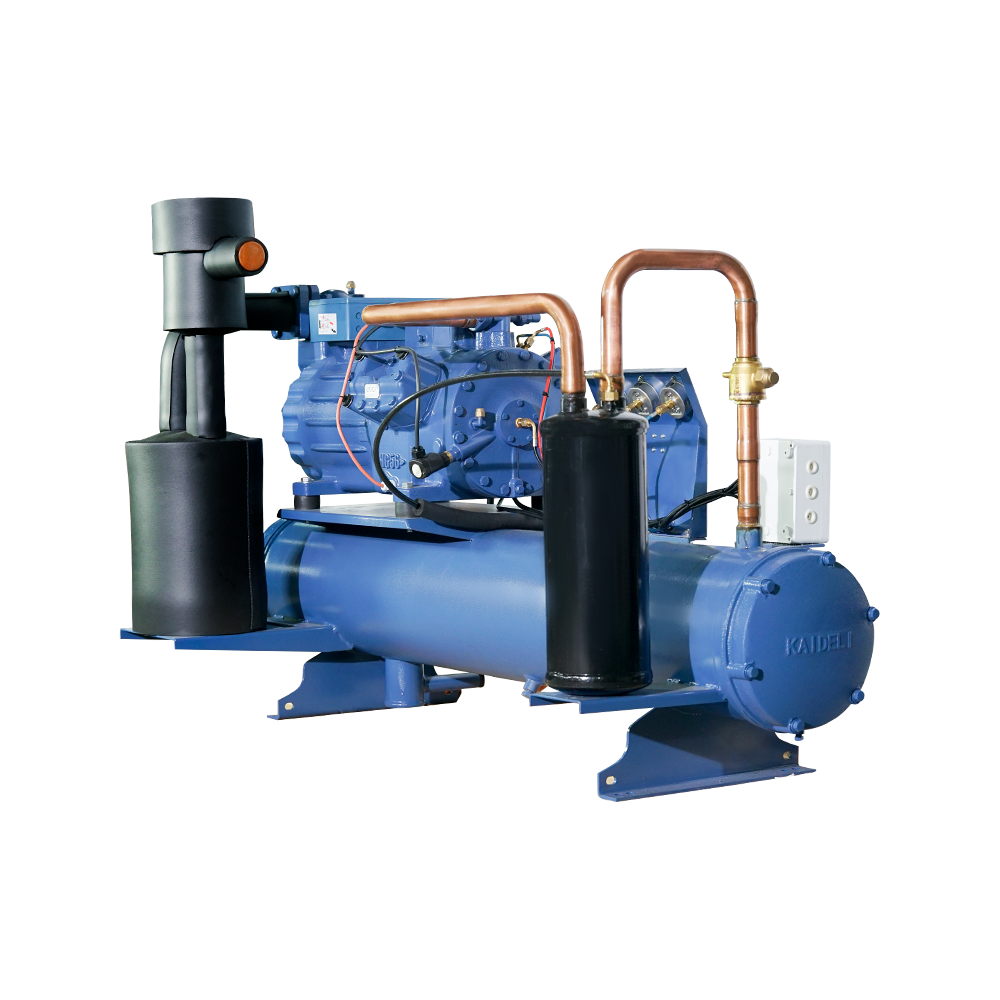

An open type condensing unit is a refrigeration system where the compressor is driven by an external motor rather than being enclosed within the same housing as the compressor. This design separates the motor from the compressor, offering several practical advantages for certain applications. The unit typically includes the compressor, air-cooled condenser, and liquid storage tank all integrated into a single system.

The KCFP Series Open Type Condensing Unit exemplifies this design approach, featuring an external motor configuration that enhances accessibility for maintenance while delivering reliable performance in demanding environments. These units are specifically engineered to compress, cool, and condense gaseous refrigerant into liquid form, which is essential for maintaining an effective refrigeration cycle.

Unlike hermetic or semi-hermetic compressors, where the motor is sealed within the compressor housing, open type units allow for easier inspection and replacement of components. This design characteristic makes them particularly suitable for applications where regular maintenance access is important or where the operating environment may affect motor performance.

Key Components of Open Type Condensing Units

To understand how these units function, it's helpful to know about their main components:

| Component | Function | Importance |

|---|---|---|

| Compressor | Compresses gaseous refrigerant to increase pressure and temperature | Creates the pressure differential needed for refrigerant circulation |

| External Motor | Provides mechanical power to drive the compressor | Allows for independent maintenance and replacement |

| Air-Cooled Condenser | Transfers heat from refrigerant to ambient air | Converts high-pressure gas to liquid refrigerant |

| Liquid Storage Tank | Stores liquid refrigerant before distribution | Ensures steady supply of refrigerant to evaporator |

| Fans and Controls | Manage airflow and system operation | Maintain efficient heat transfer and system safety |

What Are the Main Applications?

Open type condensing units find use across various industries where reliable refrigeration is essential. Their robust design and capacity for handling substantial cooling loads make them suitable for numerous commercial and industrial applications. Let's explore some of the primary sectors where these units are commonly deployed.

Cold Storage Facilities

Cold storage warehouses and facilities require dependable cooling systems to maintain consistent temperatures for perishable goods. These facilities often store large quantities of food products, pharmaceuticals, and other temperature-sensitive items. The ability of open type condensing units to provide stable and continuous refrigeration makes them a practical choice for such environments.

Large cold storage operations typically have high refrigeration demands that require powerful and reliable equipment. The open design facilitates easier maintenance, which is important in facilities where any downtime can lead to significant product losses. Additionally, these units can be customized to meet specific capacity requirements based on the size of the storage facility and the types of products being stored.

Food Processing Industry

Food processing plants need effective refrigeration at various stages of production. From initial ingredient storage to final product preservation, maintaining appropriate temperatures is critical for food safety and quality. Open type condensing units provide the necessary cooling capacity for processing lines, blast freezers, and other temperature-controlled areas within these facilities.

The food processing industry often involves harsh operating conditions with exposure to moisture, dust, and cleaning chemicals. Equipment used in these environments must be durable and capable of withstanding such conditions. The robust construction of open type units, along with the ability to service individual components, makes them well-suited for food processing applications.

Cold Chain Logistics

The cold chain encompasses all temperature-controlled aspects of the supply chain, from production to consumption. This includes refrigerated transport, distribution centers, and retail storage. Open type condensing units are frequently used in distribution centers and logistics hubs where large quantities of perishable goods are temporarily stored before being transported to their final destinations.

In cold chain applications, reliability is crucial as any interruption in temperature control can compromise product quality and safety. The straightforward design of open type units contributes to their reliability by reducing complexity and making troubleshooting more efficient. This is particularly valuable in logistics operations where rapid response to equipment issues is essential.

| Industry | Typical Applications | Key Requirements |

|---|---|---|

| Cold Storage | Warehouses, distribution centers | Consistent temperature, high capacity |

| Food Processing | Production lines, freezers | Durability, hygiene standards |

| Cold Chain | Logistics hubs, transit points | Reliability, quick maintenance |

| Supermarkets | Display cases, storage rooms | Energy efficiency, quiet operation |

| Pharmaceutical | Drug storage, temperature control | Precision, compliance with regulations |

How Do These Units Compare to Other Refrigeration Options?

When selecting refrigeration equipment, business owners often compare different types of systems to determine which best meets their requirements. Understanding the distinctions between open type condensing units and other alternatives can help in making an appropriate selection for your specific application.

Open Type vs. Hermetic Units

Hermetic compressors have the motor sealed within the compressor housing, creating a completely enclosed unit. This design protects internal components from the external environment but makes maintenance more challenging since the entire unit typically needs replacement if a major component fails. In contrast, open type units allow for individual component servicing, which can reduce long-term maintenance costs.

Hermetic units are often more compact and may be suitable for smaller applications where space is at a premium. However, for larger commercial and industrial applications, the accessibility and serviceability of open type units often make them the more practical choice. The KCFP Series Open Type Condensing Unit demonstrates how open type designs can deliver high performance while maintaining service advantages.

Open Type vs. Semi-Hermetic Units

Semi-hermetic compressors have bolted construction that allows internal access for repairs, offering a middle ground between hermetic and open type designs. While semi-hermetic units provide more serviceability than hermetic compressors, they still have the motor integrated with the compressor, which can complicate motor replacement compared to open type designs.

Open type units take serviceability a step further by completely separating the motor from the compressor. This design is particularly beneficial in environments where motors are subject to high failure rates due to operating conditions. Being able to replace or repair the motor independently of the compressor can significantly reduce maintenance expenses over the equipment's lifespan.

Capacity and Performance Considerations

When comparing different refrigeration options, capacity is an important factor to consider. Open type condensing units are typically available in higher capacity ranges suitable for large-scale applications. Their design allows for efficient heat dissipation and stable operation under heavy loads, which is essential for industrial refrigeration requirements.

Performance in different ambient conditions is another consideration. Open type units generally perform well in a wide range of temperatures, though appropriate protection may be needed in extreme environments. The air-cooled design eliminates the need for water cooling systems, which can be advantageous in areas where water is scarce or expensive.

| Feature | Open Type Units | Hermetic Units | Semi-Hermetic Units |

|---|---|---|---|

| Motor Configuration | External, separate | Internal, sealed | Internal, accessible |

| Maintenance Access | Easy component access | Limited, unit replacement | Internal access possible |

| Typical Capacity | High to very high | Low to medium | Medium to high |

| Cost Considerations | Lower maintenance costs | Higher replacement costs | Moderate repair costs |

| Common Applications | Industrial, large commercial | Small commercial, residential | Commercial, light industrial |

What Factors Should Influence the Selection Process?

Choosing the right refrigeration equipment involves evaluating multiple factors related to your specific application and operating conditions. Taking the time to carefully assess these factors can help ensure that the selected equipment will perform reliably and efficiently in your particular environment.

Cooling Requirements

The most fundamental consideration is determining your cooling requirements. This includes the total cooling capacity needed, the temperature range that must be maintained, and any specific requirements for temperature control precision. Different applications have varying cooling loads based on factors such as the size of the space, the volume of product being stored, the frequency of door openings, and the desired internal temperature.

Professional assessment of cooling requirements is recommended to ensure proper equipment sizing. Undersized equipment will struggle to maintain desired temperatures, while oversized equipment may cycle on and off frequently, reducing efficiency and increasing wear. The KCFP Series Open Type Condensing Unit is available in various capacity options to accommodate different application requirements.

Operating Environment

The environment where the equipment will operate significantly impacts the selection process. Consider factors such as ambient temperature range, humidity levels, presence of dust or contaminants, available space for installation, and ventilation capabilities. Harsh environments may require additional protective measures or specific equipment features.

For outdoor installations, weather protection and appropriate enclosure ratings are important. Indoor installations must consider ventilation for heat rejection and accessibility for maintenance operations. The location also affects the choice of components such as condenser coils and fan arrangements to ensure efficient operation under actual conditions.

Energy Efficiency Considerations

Energy consumption represents a significant portion of operating costs for refrigeration systems. Evaluating the energy efficiency of different equipment options is essential for understanding long-term operational expenses. Modern condensing units incorporate various efficiency-enhancing features such as variable speed fans, efficient compressor designs, and advanced control strategies.

While initial purchase price is an important consideration, total cost of ownership should be evaluated over the equipment's expected lifespan. More efficient units may have higher upfront costs but can deliver substantial savings through reduced energy consumption. Additionally, energy-efficient equipment may qualify for incentives or rebates in some regions.

| Selection Factor | Key Questions | Impact on Equipment Choice |

|---|---|---|

| Cooling Capacity | What is the total cooling load? | Determines unit size and configuration |

| Temperature Range | What temperatures must be maintained? | Affects compressor and refrigerant selection |

| Ambient Conditions | What are the environmental conditions? | Influences component protection needs |

| Space Availability | How much installation space is available? | Affects unit footprint and layout |

| Maintenance Access | How accessible is the installation site? | Impacts service considerations |

| Energy Costs | What are local energy rates? | Influences efficiency priority |

How Important Is Proper Installation and Setup?

Even high-quality refrigeration equipment will not perform as expected if not properly installed and configured. The installation process significantly impacts system performance, efficiency, and longevity. Understanding the importance of proper installation helps ensure that your investment delivers the expected results.

Site Preparation Requirements

Proper site preparation is essential for successful installation. This includes ensuring a level, stable foundation capable of supporting the unit's weight, providing adequate clearance around the equipment for maintenance access and airflow, and preparing appropriate electrical connections that meet the equipment's specifications. Inadequate site preparation can lead to operational problems and reduced equipment life.

The installation location must also consider factors such as noise levels, heat rejection, and potential exposure to contaminants. For outdoor installations, weather protection measures should be implemented to shield the equipment from direct exposure to rain, snow, and extreme temperatures. Proper drainage should be provided to prevent water accumulation around the unit.

Refrigerant Piping Design

The refrigerant piping system connects the condensing unit to the evaporator and other system components. Proper piping design is critical for efficient system operation. Piping must be correctly sized based on the refrigerant flow requirements, appropriately insulated to prevent heat gain or loss, and installed with proper support to prevent stress on connections.

Incorrect piping can lead to various problems including reduced efficiency, oil return issues, and compressor damage. The piping layout should minimize pressure drops while accommodating thermal expansion and contraction. Professional design and installation of the refrigerant piping system is essential for reliable operation.

Electrical Installation

Electrical installation must comply with local codes and the equipment manufacturer's specifications. This includes providing appropriate circuit protection, ensuring proper wire sizing, and implementing correct grounding practices. The electrical system should be designed to handle the unit's starting current requirements while maintaining stable voltage during operation.

Improper electrical installation can create safety hazards and cause equipment malfunctions. It's important to have qualified electrical personnel perform the installation and verify that all connections are secure and that protection devices are appropriately rated. Testing should be conducted to ensure proper operation before placing the system in service.

| Installation Aspect | Requirements | Common Issues |

|---|---|---|

| Foundation | Level, stable, weight-bearing | Uneven mounting, vibration |

| Clearance | Adequate access and airflow | Restricted service access |

| Electrical | Correct voltage, protection | Wiring errors, overload |

| Piping | Proper sizing, insulation | Pressure drops, leaks |

| Protection | Weather shielding as needed | Environmental damage |

What Maintenance Practices Ensure Long-Term Reliability?

Regular maintenance is essential for keeping refrigeration equipment operating efficiently and preventing unexpected failures. Establishing a comprehensive maintenance program helps identify potential issues before they become serious problems and extends the useful life of the equipment.

Routine Maintenance Tasks

Regular maintenance tasks include cleaning condenser coils to maintain efficient heat transfer, inspecting and cleaning fan blades and motors, checking refrigerant charge levels, inspecting electrical connections for signs of overheating or corrosion, and verifying proper operation of safety controls. These tasks should be performed according to a scheduled maintenance plan based on operating hours and environmental conditions.

The open type design of units like the KCFP Series Open Type Condensing Unit facilitates these maintenance activities by providing easy access to components. This accessibility helps ensure that maintenance tasks can be performed thoroughly and efficiently, reducing downtime and maintenance costs.

Component-Specific Maintenance

Different components require specific maintenance attention. The compressor should be regularly inspected for unusual sounds or vibrations, which may indicate developing problems. Motor bearings should be checked and lubricated according to the manufacturer's recommendations. Fan belts, where used, should be inspected for wear and proper tension.

The condenser coil is particularly important as it directly affects system efficiency. Dirty or blocked coils reduce heat transfer capacity, causing the system to work harder and consume more energy. Regular cleaning based on operating conditions helps maintain peak performance. In dusty environments, more frequent cleaning may be necessary.

Monitoring and Record Keeping

System monitoring provides valuable information about equipment performance and can help identify developing problems. Key parameters to monitor include operating pressures and temperatures, energy consumption patterns, and run times. Recording this information creates a history that can be useful for diagnosing problems and planning maintenance activities.

Modern equipment may include monitoring capabilities that provide real-time performance data. Even without such features, manual data collection can be beneficial. Establishing baseline performance parameters after installation allows for comparison over time to identify any performance degradation that may indicate maintenance needs.

| Maintenance Category | Tasks | Frequency |

|---|---|---|

| Daily/Weekly | Visual inspection, operating temperatures | Ongoing monitoring |

| Monthly | Coil cleaning, electrical inspection | Regular schedule |

| Quarterly | Comprehensive inspection, refrigerant check | Detailed assessment |

| Annually | Major service, component evaluation | Thorough maintenance |

| As Needed | Repairs, component replacement | Responsive action |

What Are Common Troubleshooting Scenarios?

Even well-maintained equipment may occasionally experience operational issues. Understanding common problems and their potential causes can help in identifying issues quickly and implementing appropriate solutions. This knowledge is valuable for both facility managers and service technicians.

Insufficient Cooling Capacity

When a system fails to maintain desired temperatures, the first step is to check for obvious issues such as dirty condenser coils, improper airflow, or incorrect thermostat settings. Restricted airflow around the condenser can significantly reduce heat rejection capacity. Cleaning coils and ensuring adequate ventilation often resolves this issue.

If cooling problems persist after addressing airflow issues, other potential causes should be investigated. These may include low refrigerant charge, compressor problems, or issues with the expansion device. Professional diagnosis may be needed to identify the root cause and implement appropriate repairs.

High Operating Pressures

Elevated operating pressures can indicate various system problems. High head pressure often results from dirty condenser coils, inadequate airflow, or overcharging of refrigerant. Checking and cleaning condenser coils is typically the first troubleshooting step. Ensuring that fans are operating properly and that air discharge is not restricted is also important.

High suction pressure may indicate issues such as overcharging, evaporator problems, or compressor inefficiency. System performance data should be compared to manufacturer specifications to determine whether pressures are within acceptable ranges. Persistent pressure issues require professional evaluation to identify underlying causes.

Unusual Noises or Vibrations

Abnormal sounds or vibrations often indicate mechanical problems. Possible causes include loose mounting bolts, worn bearings, belt issues (if applicable), or internal compressor problems. The source of the noise should be identified through careful observation. Isolating whether the sound is coming from the compressor, motor, fans, or other components helps guide troubleshooting efforts.

In open type units, motor issues can often be addressed without replacing the entire compressor assembly, which is one of the advantages of this design. However, internal compressor problems typically require professional repair or replacement. Addressing unusual sounds promptly can prevent more serious damage.

| Symptom | Possible Causes | Initial Troubleshooting |

|---|---|---|

| Insufficient Cooling | Dirty coils, low charge, airflow issues | Clean coils, check airflow, verify settings |

| High Head Pressure | Dirty condenser, overcharge, fan problems | Clean condenser, check fan operation |

| High Suction Pressure | Overcharge, evaporator issues, compressor problems | Check charge, inspect evaporator |

| Unusual Noises | Loose components, worn bearings, internal issues | Secure mounting, inspect bearings |

| Frequent Cycling | Improper control settings, capacity issues | Verify thermostat, check system sizing |

How Does Refrigerant Choice Impact System Performance?

The choice of refrigerant significantly affects system performance, efficiency, and environmental impact. Different refrigerants have varying thermodynamic properties that influence capacity and efficiency. Understanding refrigerant characteristics is important for selecting appropriate equipment and complying with environmental regulations.

Environmental Considerations

Environmental regulations have driven significant changes in refrigerant selection in recent years. Many traditional refrigerants have high Global Warming Potential (GWP) and are being phased out in favor of more environmentally friendly alternatives. When selecting new equipment, it's important to consider the refrigerant used and its compliance with current and anticipated regulations.

The KCFP Series Open Type Condensing Unit can be configured with various refrigerant options to meet specific application requirements and regulatory environments. Understanding the refrigerant characteristics helps ensure that the system meets both performance needs and environmental compliance requirements.

Performance Characteristics

Different refrigerants have different performance characteristics that affect system capacity and efficiency. Factors to consider include cooling capacity per unit of refrigerant flow, pressure characteristics, compatibility with system components, and suitability for the desired temperature range. Some refrigerants offer better efficiency at certain temperature ranges than others.

The choice of refrigerant also affects component sizing and selection. Systems designed for one refrigerant may not be suitable for direct conversion to another without modifications. When evaluating equipment options, it's important to consider the refrigerant used and how it matches your application requirements.

Handling and Safety Considerations

Different refrigerants have varying safety classifications regarding flammability and toxicity. Proper handling procedures and safety equipment must be used based on the specific refrigerant properties. Training for personnel who work with refrigeration systems should include information about the safe handling of the refrigerants used in those systems.

Refrigerant containment is important both for environmental reasons and for maintaining system performance. Leaks not only release refrigerant into the atmosphere but also reduce system capacity and efficiency. Regular leak checking and prompt repair of any leaks identified is essential for responsible system operation.

| Refrigerant Consideration | Impact | Factors to Evaluate |

|---|---|---|

| Environmental Impact | Regulatory compliance, sustainability | GWP, ODP, phase-out schedules |

| Efficiency | Energy consumption, operating costs | Thermodynamic properties, application suitability |

| Safety | Handling requirements, equipment design | Flammability, toxicity classification |

| Availability | Serviceability, cost | Supply chain, local regulations |

| Compatibility | System design, retrofit potential | Material compatibility, oil requirements |

What Are the Cost Considerations?

When evaluating refrigeration equipment, cost considerations extend beyond the initial purchase price. A comprehensive evaluation should include total cost of ownership, which encompasses acquisition costs, installation expenses, operating costs, maintenance costs, and eventual disposal or replacement costs. Understanding these various cost components helps in making financially sound decisions.

Initial Investment

The initial investment includes the equipment purchase price, any necessary modifications to the installation site, professional installation costs, and initial setup expenses. While it may be tempting to select equipment based primarily on purchase price, this approach may not result in the lowest overall cost over the equipment's lifespan.

Higher quality equipment with advanced features may have a higher initial cost but can deliver substantial savings through reduced energy consumption, lower maintenance requirements, and longer service life. Evaluating the total cost of ownership rather than just the purchase price provides a more accurate basis for comparison.

Operating Costs

Energy consumption typically represents the largest ongoing cost for refrigeration systems. Selecting energy-efficient equipment and ensuring proper installation and maintenance can significantly reduce operating expenses. The efficiency gains from modern equipment can offset a higher initial purchase price within a reasonable timeframe through reduced energy bills.

Other operating costs include regular maintenance expenses, refrigerant replacement if leaks occur, and repair costs. Equipment designed for easy maintenance, such as open type condensing units, can reduce maintenance costs by making service activities more efficient. Predictable maintenance expenses should be budgeted as part of ongoing operations.

Lifecycle Cost Analysis

Lifecycle cost analysis considers all costs associated with equipment over its entire operational lifespan. This includes initial acquisition costs, installation expenses, operating costs, maintenance costs, and residual value at end of life. Performing this analysis provides a more complete picture of the true cost of different equipment options.

Factors such as expected equipment lifespan, energy cost projections, maintenance requirements, and potential efficiency improvements over time should be included in the analysis. This comprehensive approach helps identify the most cost-effective solution for the specific application rather than simply selecting the equipment with the lowest initial price.

| Cost Category | Description | Optimization Strategies |

|---|---|---|

| Acquisition | Equipment purchase, installation | Compare total value, not just price |

| Operation | Energy, routine maintenance | Efficient operation, preventive maintenance |

| Repairs | Unscheduled maintenance | Quality equipment, prompt repairs |

| Disposal | Replacement, environmental compliance | Proper refrigerant recovery |

| Opportunity | Lost production, product loss | Reliable equipment, backup systems |

What Future Trends Are Emerging in Refrigeration Technology?

The refrigeration industry continues to evolve with technological advancements and changing market requirements. Staying informed about emerging trends helps businesses prepare for future developments and make decisions that will remain relevant as technology progresses.

Energy Efficiency Improvements

Energy efficiency remains a primary focus for refrigeration equipment development. Manufacturers continue to introduce innovations that reduce energy consumption while maintaining or improving cooling capacity. These include advanced compressor designs, improved heat exchanger configurations, variable speed technology, and sophisticated control systems that optimize operation based on real-time conditions.

Integration with building management systems and smart grid technology enables more sophisticated control strategies that can further enhance efficiency. The ability to monitor and adjust system operation remotely provides opportunities for optimization that were not previously possible. These advancements contribute to reduced operating costs and improved environmental performance.

Alternative Refrigerants

The transition to lower GWP refrigerants continues to drive changes in refrigeration equipment design. New refrigerants with improved environmental profiles are being introduced, and equipment must be adapted to accommodate their specific characteristics. This includes component modifications to handle different pressure and temperature requirements.

Natural refrigerants such as carbon dioxide, ammonia, and hydrocarbons are gaining interest for certain applications due to their very low environmental impact. Equipment designs are evolving to safely and efficiently utilize these refrigerants where appropriate. The KCFP Series Open Type Condensing Unit incorporates design flexibility to accommodate evolving refrigerant requirements.

Smart Technology Integration

The integration of smart technology and Internet of Things (IoT) capabilities is transforming how refrigeration systems are monitored and controlled. Advanced sensors and connectivity enable real-time performance monitoring, predictive maintenance, and remote diagnostics. These capabilities help identify issues before they cause failures and optimize system operation for maximum efficiency.

Data analytics applied to performance information can reveal patterns and opportunities for improvement that would be difficult to identify otherwise. This information can be used to fine-tune system operation, schedule maintenance more effectively, and make informed decisions about equipment upgrades or replacements.

| Trend | Description | Implications |

|---|---|---|

| Energy Efficiency | Advanced components, smart controls | Lower operating costs, reduced environmental impact |

| Alternative Refrigerants | Low GWP options, natural refrigerants | Regulatory compliance, equipment adaptations |

| Smart Technology | IoT integration, advanced monitoring | Improved reliability, predictive maintenance |

| Modular Design | Flexible configurations, scalability | Easier customization, capacity adjustments |

| Sustainability Focus | Reduced environmental impact | Corporate responsibility, regulatory compliance |

Conclusion

Open type condensing units represent a practical solution for many industrial and large commercial refrigeration applications. Their design offers advantages in terms of serviceability, capacity, and performance that make them well-suited for demanding environments where reliability and maintenance access are important considerations.

Understanding the various aspects of these systems—from their components and applications to installation requirements and maintenance needs—enables informed decision-making when selecting refrigeration equipment. The KCFP Series Open Type Condensing Unit exemplifies the capabilities of this equipment category, providing reliable performance for applications ranging from cold storage to food processing and cold chain logistics.

As technology continues to evolve and environmental requirements become increasingly stringent, staying informed about equipment options and industry trends helps ensure that your refrigeration investments will meet both current needs and future requirements. Working with knowledgeable equipment suppliers and service providers provides additional support in selecting and maintaining appropriate refrigeration solutions for your specific applications.

English

English 中文简体

中文简体