Introduction to Condensing Units in Modern Refrigeration

Refrigeration technology has advanced significantly over the past decade, with various components working together to create efficient cooling systems. Among these components, condensing units play a crucial role in the overall functionality of refrigeration systems. These units are responsible for dissipating heat absorbed from the refrigerated space, allowing the system to maintain desired temperatures consistently.

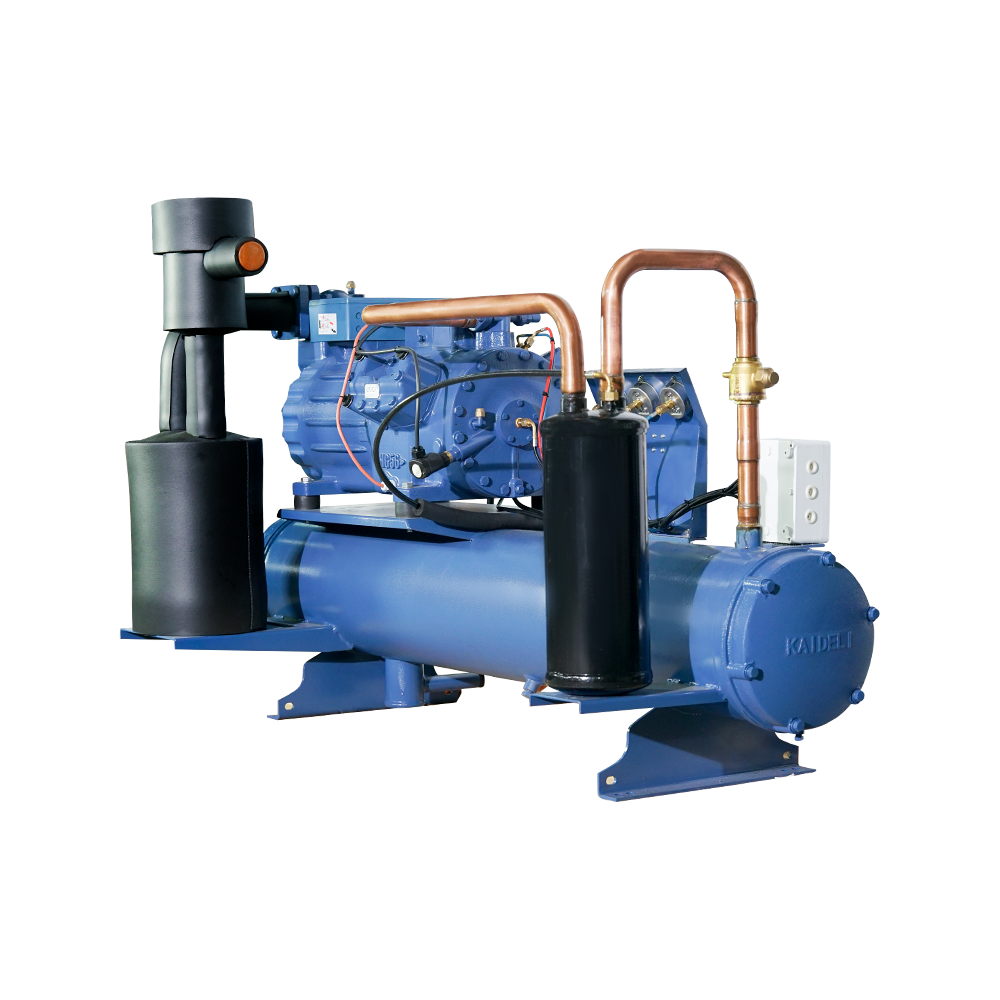

Open type compressor condensing units have gained considerable attention in recent years due to their design flexibility and maintenance advantages. These systems differ from hermetically sealed units by allowing access to internal components, which can be beneficial for certain applications and operational requirements. The KCWP Series Open Type Compressor Condensing Unit exemplifies this category of refrigeration equipment, offering various configuration options to meet diverse industry needs.

When selecting a condensing unit for a refrigeration application, numerous factors come into consideration. Understanding these factors can help businesses make informed decisions that align with their operational requirements, efficiency goals, and budget considerations. This article explores key aspects of open type compressor condensing units to provide valuable insights for those considering such equipment for their refrigeration needs.

Core Components and Construction

The design and construction of condensing units significantly influence their performance characteristics and reliability. Understanding these components can help potential buyers evaluate different options and select units that best match their requirements.

Compressor Technology

The compressor serves as the heart of any refrigeration system, responsible for circulating refrigerant and creating the pressure differential necessary for heat transfer. The quality of the compressor directly impacts the system's efficiency, reliability, and operational lifespan. Many reputable manufacturers utilize compressors from established brands known for their engineering excellence and product reliability.

For instance, the KCWP Series Open Type Compressor Condensing Unit incorporates Bitzer original compressor heads, which are recognized in the industry for their robust performance and durability. Bitzer has established itself as a reputable compressor manufacturer, with products that demonstrate consistent performance across various operating conditions.

Condensing System Variations

Condensing units typically incorporate either water-cooled or air-cooled systems, each with distinct advantages and considerations. The choice between these approaches depends largely on the specific application, environmental conditions, and operational preferences.

Both cooling methods have their place in modern refrigeration applications, with selection often based on factors such as available resources, ambient conditions, noise considerations, and initial investment costs.

Heat Exchange Technologies

The efficiency of heat transfer within a condensing unit significantly impacts overall system performance. Manufacturers employ various technologies to enhance heat exchange efficiency, with recent advances focusing on increased surface area and improved fluid dynamics.

Water-cooled systems often incorporate external threaded heat exchange tubes, which provide increased surface area for heat transfer. These specialized tubes comply with industry standards such as NB/T47012-2020, ensuring quality and consistency in performance. Air-cooled systems typically utilize internal threaded heat exchange tubes combined with corrugated aluminum fins to maximize heat dissipation efficiency.

| Component | Water-Cooled System | Air-Cooled System |

|---|---|---|

| Primary Cooling Method | Water circulation through heat exchange tubes | Air movement over finned tubes |

| Typical Heat Exchange Features | External threaded tubes | Internal threaded tubes with corrugated fins |

| Common Applications | Facilities with adequate water supply | Locations with limited water resources |

| Ventilation Requirements | Indoor installation often possible | Requires adequate airflow access |

Performance Characteristics and Efficiency

Evaluating the performance characteristics of condensing units helps businesses understand how different models might perform under various operating conditions and load requirements.

Energy Efficiency Considerations

Energy consumption represents a significant operational cost for refrigeration systems, making efficiency an important consideration when selecting equipment. Modern condensing units incorporate various design elements intended to improve energy efficiency and reduce operating costs over time.

The condenser capacity directly influences the system's ability to reject heat efficiently. Units with larger condenser capacities typically demonstrate better performance under high ambient temperature conditions, maintaining consistent cooling output even during demanding operational periods. The KCWP Series Open Type Compressor Condensing Unit features condensers with substantial capacity designed to provide consistent performance across varying load conditions.

Operational Stability and Reliability

Reliable operation is essential for refrigeration systems, particularly in applications where temperature consistency directly impacts product quality and safety. Several factors contribute to the operational stability of condensing units, including component quality, design philosophy, and manufacturing standards.

High-quality accessories and components throughout the system contribute to reliable operation and extended equipment lifespan. Manufacturers who prioritize quality in their component selection typically produce units that demonstrate consistent performance over longer operational periods, reducing maintenance requirements and downtime.

Noise Level Considerations

For applications in noise-sensitive environments, the acoustic characteristics of condensing units become an important selection criterion. Modern air-cooled systems often incorporate external rotor fans designed to operate with reduced noise levels while maintaining adequate airflow for heat dissipation.

These specialized fans balance airflow requirements with noise reduction, making them suitable for installations in areas where noise emissions must be minimized. This feature is particularly valuable for applications in food retail environments, medical facilities, or other locations where equipment noise could impact operations or customer experience.

| Performance Aspect | Impact on Operations | Typical Design Approaches |

|---|---|---|

| Energy Efficiency | Directly affects operating costs | Enhanced heat exchange surfaces, efficient compressors |

| Operational Stability | Influences product quality and system reliability | Quality components, robust construction |

| Noise Generation | Impacts environment and workplace comfort | Low-noise fan designs, vibration dampening |

| Load Variation Handling | Affects performance under different conditions | Variable speed components, capacity modulation |

Applications and Industry Usage

Open type compressor condensing units find application across numerous industries, each with specific requirements that influence equipment selection and configuration.

Food Industry Applications

The food industry encompasses one of the largest user bases for refrigeration equipment, with applications ranging from fresh-keeping to specialized cold storage. Temperature control remains critical throughout the food supply chain, from production facilities to retail outlets.

In food retail environments, refrigeration systems must maintain consistent temperatures to ensure product quality and safety while operating efficiently in customer-facing spaces. The KCWP Series Open Type Compressor Condensing Unit can be configured for various food preservation applications, providing flexibility for different display cases, walk-in coolers, and storage rooms.

Food processing facilities often require robust refrigeration systems capable of handling significant heat loads generated during production processes. These applications benefit from condensing units with substantial capacity and efficient heat rejection capabilities to maintain consistent temperatures despite fluctuating production demands.

Pharmaceutical and Medical Applications

Temperature control in pharmaceutical and medical applications often involves precise requirements with minimal tolerance for deviation. Refrigeration systems in these environments must provide consistent performance while meeting regulatory requirements for storage conditions of medications, vaccines, and biological samples.

Pharmaceutical storage facilities, hospitals, and research laboratories rely on refrigeration equipment that maintains precise temperature ranges regardless of external conditions. The reliability of these systems directly impacts product efficacy and patient safety, making quality equipment selection particularly important for these applications.

Industrial and Manufacturing Applications

Beyond food and medicine, various industrial processes incorporate refrigeration for product cooling, equipment temperature control, or environmental conditioning. These applications often have specific requirements based on the nature of the industrial process and the operating environment.

Manufacturing facilities might utilize refrigeration for process cooling, equipment temperature regulation, or environmental control in production areas. The versatility of open type compressor condensing units makes them suitable for a range of industrial applications where flexibility and maintainability are valued.

| Industry Sector | Primary Applications | Key Considerations |

|---|---|---|

| Food Industry | Fresh-keeping, cold storage, display cases | Temperature consistency, energy efficiency, noise levels |

| Pharmaceutical/Medical | Medication storage, laboratory cooling | Precise temperature control, reliability, compliance |

| Industrial/Manufacturing | Process cooling, equipment temperature control | Capacity requirements, durability, custom configuration |

| Ice Production | Commercial ice making equipment | Rapid temperature reduction, consistent performance |

Selection Factors and Decision Making

Choosing the appropriate condensing unit involves evaluating multiple factors to ensure the selected equipment meets specific operational requirements while providing value over its operational lifespan.

Temperature Range Capabilities

Different applications require different temperature ranges, making this capability an important consideration during the selection process. Refrigeration needs vary significantly between applications such as fresh-keeping (typically around 0°C to 5°C), freezing (-18°C or lower), and specialized low-temperature applications.

The versatility of modern condensing units allows for configuration across a wide range of temperature requirements. When evaluating options, businesses should consider both their current needs and potential future applications to ensure the selected equipment provides adequate flexibility.

Capacity and Sizing Considerations

Properly sizing a condensing unit for the application is crucial for achieving efficient operation and satisfactory performance. Undersized units may struggle to maintain desired temperatures under peak loads, while oversized units can operate inefficiently and may experience cycling issues that reduce equipment lifespan.

Calculating the required capacity involves considering factors such as the size of the refrigerated space, the thermal load from products, ambient temperature conditions, and anticipated usage patterns. Professional assessment of these factors can help ensure appropriately sized equipment for each specific application.

Installation Environment Factors

The physical environment where the condensing unit will be installed influences both the selection process and the configuration of the equipment. Factors such as available space, ambient temperature range, ventilation capabilities, and noise requirements all impact the suitability of different options.

For example, indoor installations typically require water-cooled systems or specialized ducting arrangements for air-cooled units, while outdoor installations must account for weather protection and ambient temperature extremes. Understanding these environmental factors helps ensure the selected equipment can operate reliably under actual installation conditions.

| Selection Factor | Evaluation Considerations | Potential Impact |

|---|---|---|

| Temperature Range | Current and future application requirements | Equipment flexibility and applicability |

| Capacity Requirements | Thermal load calculations, usage patterns | Performance under various conditions |

| Installation Environment | Available space, ambient conditions, noise restrictions | System configuration and suitability |

| Maintenance Accessibility | Available service access, technical resources | Long-term operational practicality |

Maintenance and Service Considerations

The open design of these compressor condensing units presents specific maintenance advantages that are valuable for certain applications and operational models.

Accessibility Benefits

One of the distinctive features of open type compressor condensing units is their accessibility for maintenance and service activities. Unlike hermetically sealed units, which typically require specialized procedures for internal component access, open type designs allow technicians to directly inspect and service internal components as needed.

This accessibility can be particularly valuable for operations with on-site technical capabilities or those in locations where specialized service personnel might have limited availability. The ability to perform routine maintenance and minor repairs in-house can reduce service response times and associated costs.

Service Requirements

While open type designs offer maintenance advantages, they also require regular maintenance activities to ensure continued reliable operation. These typically include periodic inspections of components, cleaning of heat exchange surfaces, lubrication of moving parts, and verification of proper refrigerant charge.

Establishing a regular maintenance schedule helps prevent unexpected failures and ensures the equipment operates efficiently throughout its service life. The quality of components used in the construction of the unit, such as those found in the KCWP Series Open Type Compressor Condensing Unit, can influence the frequency and extent of required maintenance activities.

Component Replacement Considerations

The modular design of many open type condensing units facilitates component replacement when necessary. This approach can extend the operational life of the overall system by allowing individual components to be replaced rather than requiring complete system replacement when specific parts reach the end of their service life.

This characteristic aligns with sustainability considerations by reducing waste and allowing for continued use of functional components. It also provides flexibility for future upgrades as technology advances, potentially improving system efficiency without complete replacement.

Economic Considerations

The financial aspects of condensing unit selection encompass both initial investment costs and ongoing operational expenses, requiring a comprehensive evaluation to understand the total cost of ownership.

Initial Investment vs. Operational Costs

When evaluating condensing units, it's important to consider both the purchase price and the ongoing operational costs over the equipment's service life. While units with higher efficiency ratings typically command a higher initial price, they may provide significant savings through reduced energy consumption over time.

The calculation of return on investment should factor in energy costs based on local rates, anticipated usage patterns, and the efficiency characteristics of the equipment under consideration. This longer-term perspective helps identify options that provide value throughout their operational life rather than focusing solely on initial purchase price.

Equipment Lifespan and Depreciation

The expected operational lifespan of condensing units varies based on usage intensity, maintenance quality, and operating conditions. Equipment constructed with high-quality components and designed for durability typically provides longer service life and more predictable depreciation schedules.

Businesses should consider the anticipated service life when evaluating options, as longer-lasting equipment may provide better value even if it carries a higher initial price tag. The ability to maintain and service components, as mentioned earlier, can further extend the operational life of open type condensing units.

Residual Value Considerations

At the end of their service life in a particular application, condensing units may retain residual value through resale or repurposing for different applications. The modularity and serviceability of open type designs can influence the residual value of the equipment when it's time for replacement or upgrade.

Equipment from reputable manufacturers with established service networks and component availability typically commands higher residual values due to continued support availability and confidence in equipment quality.

Frequently Asked Questions

What are the primary differences between water-cooled and air-cooled condensing units?

Water-cooled systems use water circulation through heat exchange tubes to reject heat, typically offering higher efficiency in moderate ambient conditions and requiring less space for the condensing unit itself. These systems are well-suited for facilities with adequate water supply and appropriate water treatment capabilities.

Air-cooled systems utilize fans to move ambient air across finned tubes for heat rejection, making them suitable for locations where water resources are limited or water treatment would be impractical. While generally requiring more space for proper airflow, these systems have simpler infrastructure requirements and avoid water-related maintenance considerations.

How do I determine the appropriate capacity for my application?

Determining the appropriate capacity requires evaluating several factors including the volume of the refrigerated space, the thermal characteristics of products being stored, the temperature difference between the desired interior temperature and expected ambient conditions, and anticipated usage patterns such as door openings and product loading.

Professional assessment by refrigeration specialists can help calculate the required capacity accurately, considering both steady-state loads and transient conditions such as product pulldown after loading warm products. Oversizing should be avoided as it can lead to inefficient operation and increased wear on components.

What maintenance does an open type compressor condensing unit require?

Regular maintenance typically includes inspection of electrical connections, cleaning of heat exchange surfaces, checking and adjusting belt tension if applicable, verifying proper refrigerant charge, lubricating bearings as specified by the manufacturer, and testing safety controls and operating pressures.

While open type designs facilitate access for these maintenance activities, they should still be performed by qualified technicians familiar with the specific equipment and applicable safety regulations. Establishing a preventive maintenance schedule helps ensure reliable operation and can extend equipment service life.

Can open type condensing units be used in food service environments with customer presence?

Yes, open type condensing units can be appropriate for food service environments when properly configured and installed. Modern air-cooled units incorporate low-noise fan designs that make them suitable for customer-facing areas. Additionally, the units can be installed in separate mechanical rooms with appropriate ducting to further reduce noise impact on customer spaces.

Proper installation following manufacturer recommendations and local regulations ensures safe operation in food service environments. The reliability of components like those in the KCWP Series Open Type Compressor Condensing Unit helps maintain consistent temperatures important for food safety and quality.

What factors should I consider when choosing between different condensing unit manufacturers?

When evaluating manufacturers, consider their industry reputation, the quality of components used in their equipment, the availability of technical support and spare parts, warranty terms, and compliance with relevant industry standards. Manufacturers who use established compressor brands like Bitzer typically demonstrate a commitment to quality components.

Additionally, consider the manufacturer's experience with applications similar to yours, their track record for reliability, and the availability of local service technicians familiar with their equipment. These factors can significantly impact your long-term experience with the equipment.

| Question Category | Key Considerations |

|---|---|

| Cooling Method Selection | Available resources, space constraints, infrastructure requirements |

| Capacity Determination | Thermal load calculations, usage patterns, safety margins |

| Maintenance Requirements | Frequency of activities, technical resources, service access |

| Application Suitability | Temperature requirements, environmental conditions, noise restrictions |

| Manufacturer Evaluation | Component quality, support availability, industry reputation |

Conclusion

Selecting the appropriate condensing unit for refrigeration applications requires careful consideration of multiple factors ranging from technical specifications to operational requirements and economic considerations. Open type compressor condensing units offer valuable advantages in terms of maintainability and service access, making them suitable for various applications across different industries.

The KCWP Series Open Type Compressor Condensing Unit represents one option in this category of equipment, incorporating quality components and design elements intended to provide reliable performance across diverse applications. When evaluating any condensing unit, potential buyers should consider their specific requirements regarding temperature range, capacity, installation environment, and maintenance capabilities.

By understanding the technical aspects, application considerations, and economic factors associated with condensing unit selection, businesses can make informed decisions that align with their operational needs and provide value throughout the equipment's service life. Consulting with refrigeration specialists and manufacturers can provide additional insights specific to particular applications and help ensure appropriate equipment selection.

As refrigeration technology continues to advance, equipment options will likely evolve with improved efficiency characteristics, enhanced monitoring capabilities, and new design approaches. Staying informed about these developments can help businesses make strategic decisions about their refrigeration infrastructure that support their operational objectives both now and in the future.

English

English 中文简体

中文简体