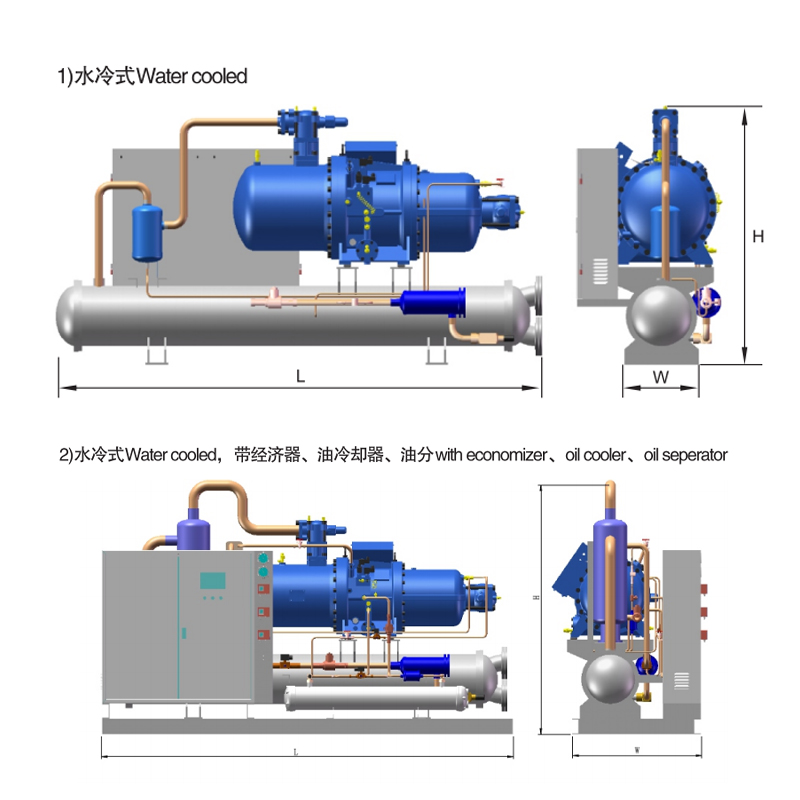

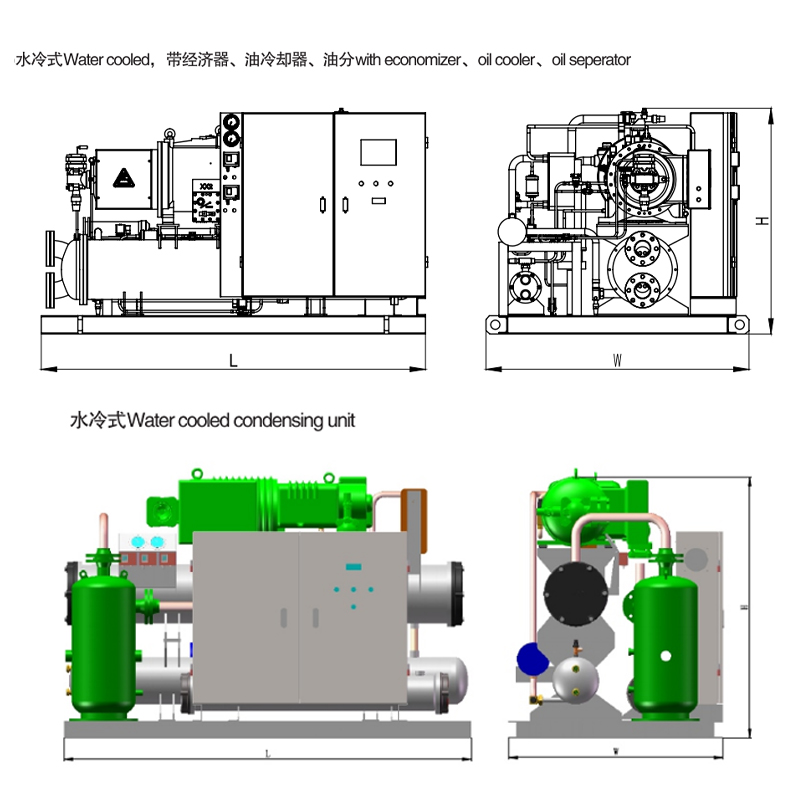

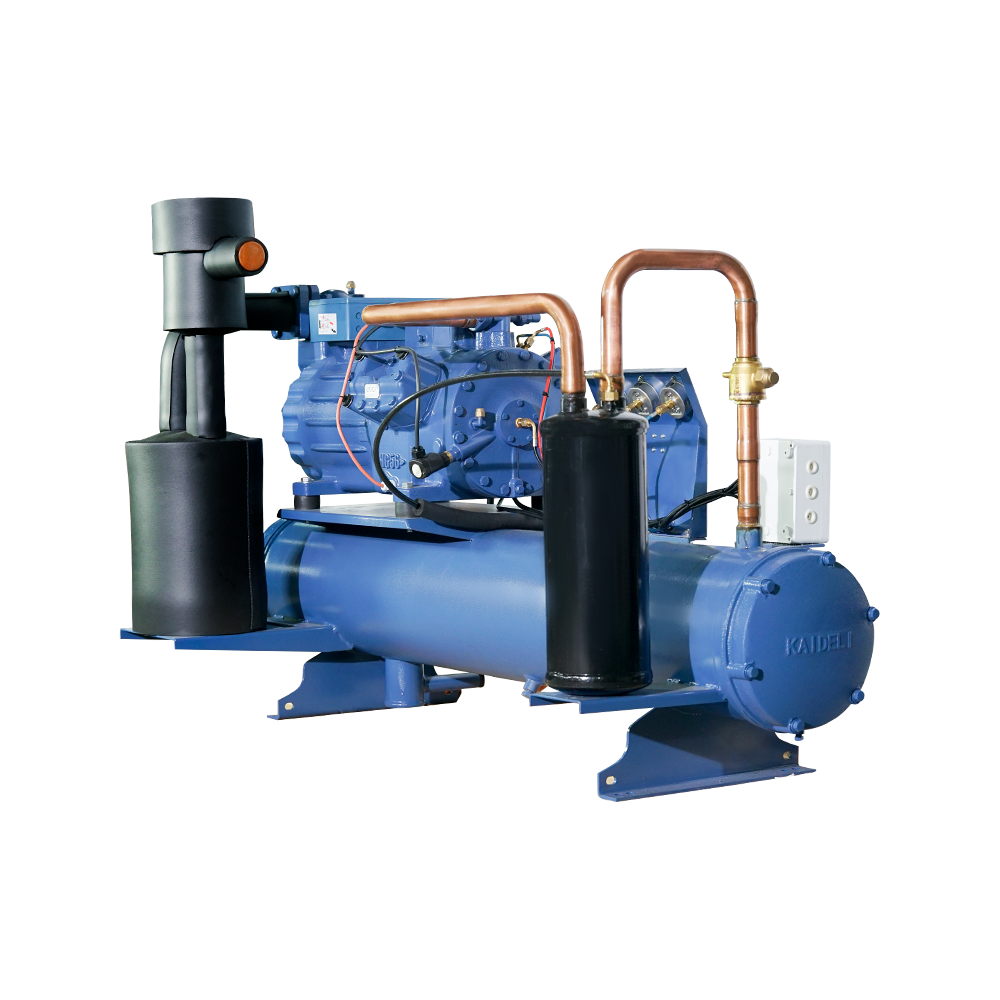

KCWS series semi-enclosed piston water-cooled compressor condensing unit is a professional refrigeration equipment developed for freezing and quick freezing environments. It can operate stably in low temperature environments of -25℃~-50℃. It is widely used in food quick freezing processing, industrial low temperature refrigeration, pharmaceutical cold chain storage and other scenarios, providing efficient refrigeration support for various places requiring ultra-low temperature refrigeration.

1. Two-stage compression technology: According to the characteristics of piston compressors, two-stage compression is used when the compression ratio is greater than 8~10; for models using R22 refrigerant, when the evaporation temperature is lower than -30℃, two-stage compression can ensure efficient operation of the system.

2. Air-cooled condenser: High-speed punch punching and secondary flanging process are adopted, and the copper tube and fin are closely combined through mechanical expansion tube, which reduces the contact thermal resistance and improves the heat exchange efficiency by more than 15%.

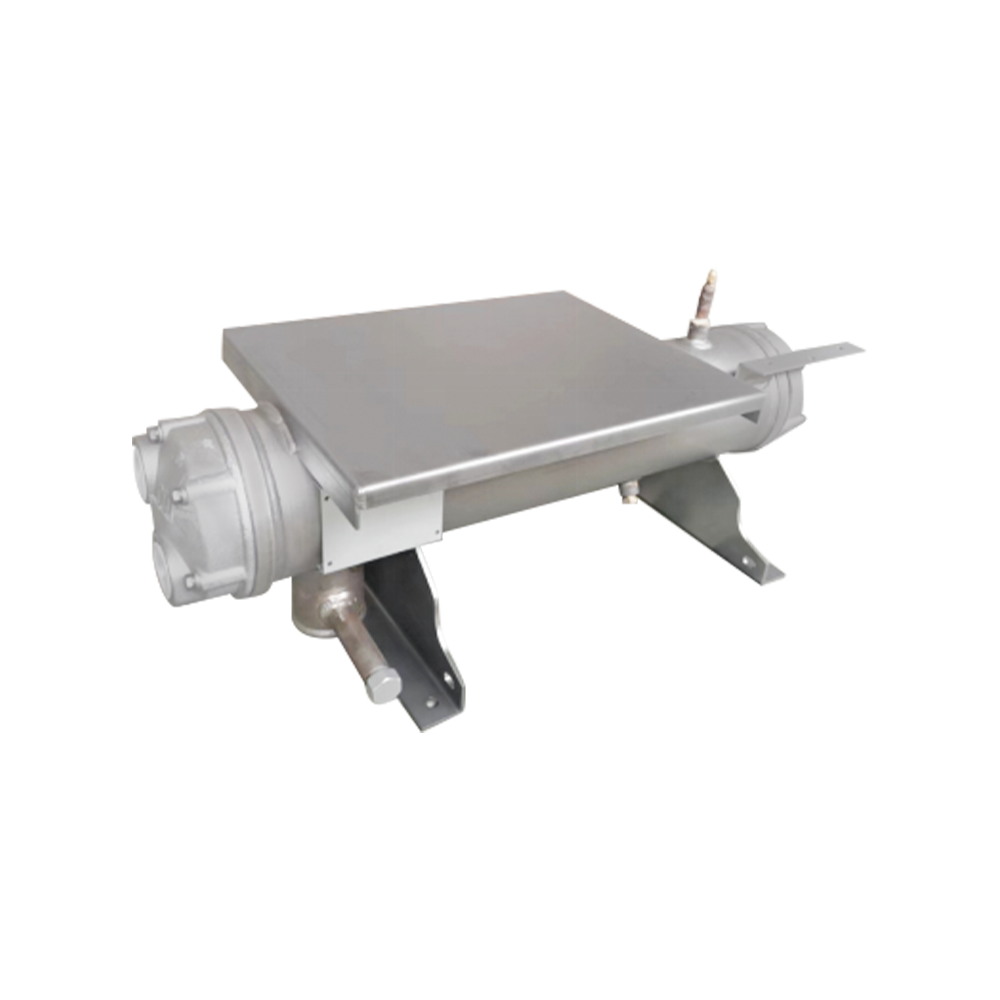

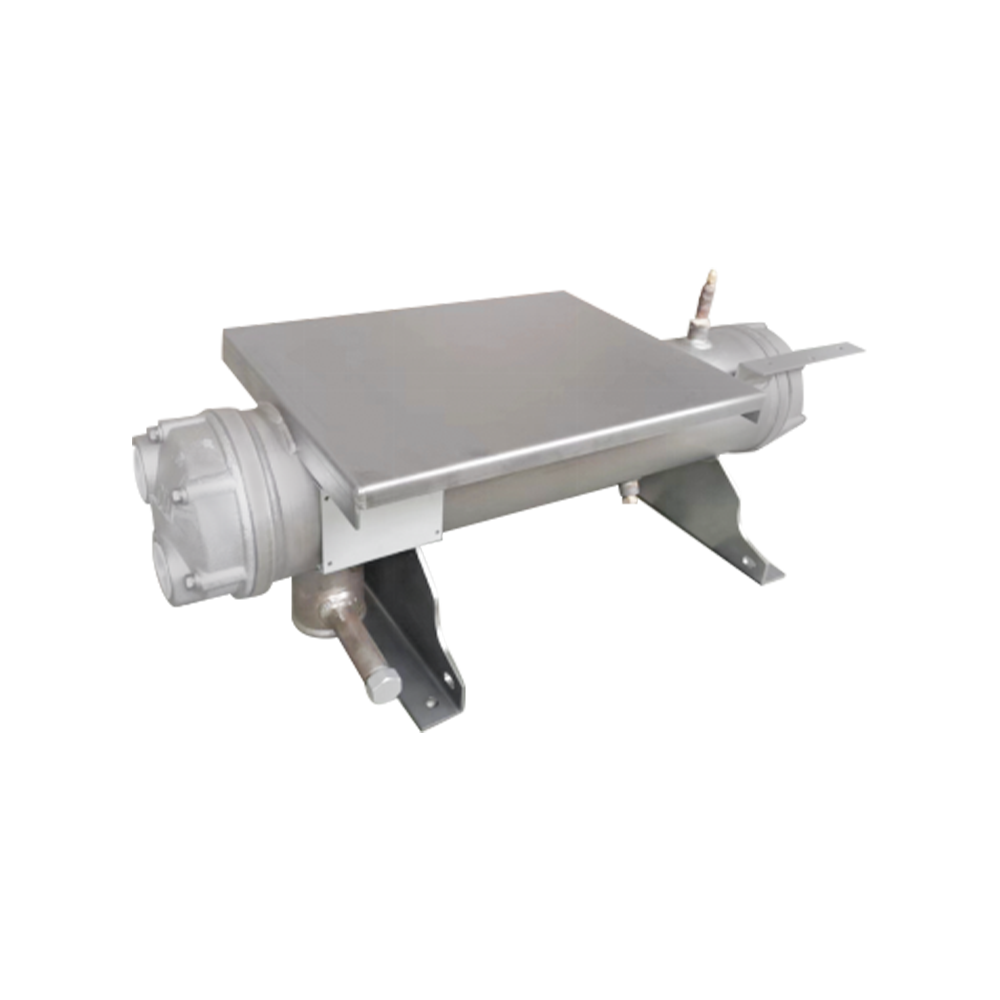

3. Shell and tube water condenser: Use high-efficiency externally threaded copper tubes, and enhance the heat transfer design on the outside of the tubes. Combined with the JB/T 4750-2003 "Pressure Vessels for Refrigeration Devices" standard, it is manufactured to ensure pressure resistance and long-term operating reliability. The condenser has both liquid storage function and does not require an additional liquid storage device.

4. Safety and control: The dual pressure controller monitors the high and low pressure status of the system in real time. When the pressure exceeds the set threshold (such as the high pressure protection value of the R22 system 2.4MPa), it automatically shuts down to prevent the compressor from overloading. The intercooler assembly can reduce the interstage exhaust temperature, improve lubrication conditions and extend the life of components.

5. Customized expansion: According to customer needs, accessories such as gas-liquid separators (to prevent liquid hammer) and oil pressure differential controllers (to monitor the lubrication system) can be added to meet the special needs of load fluctuations or full liquid evaporation systems.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026