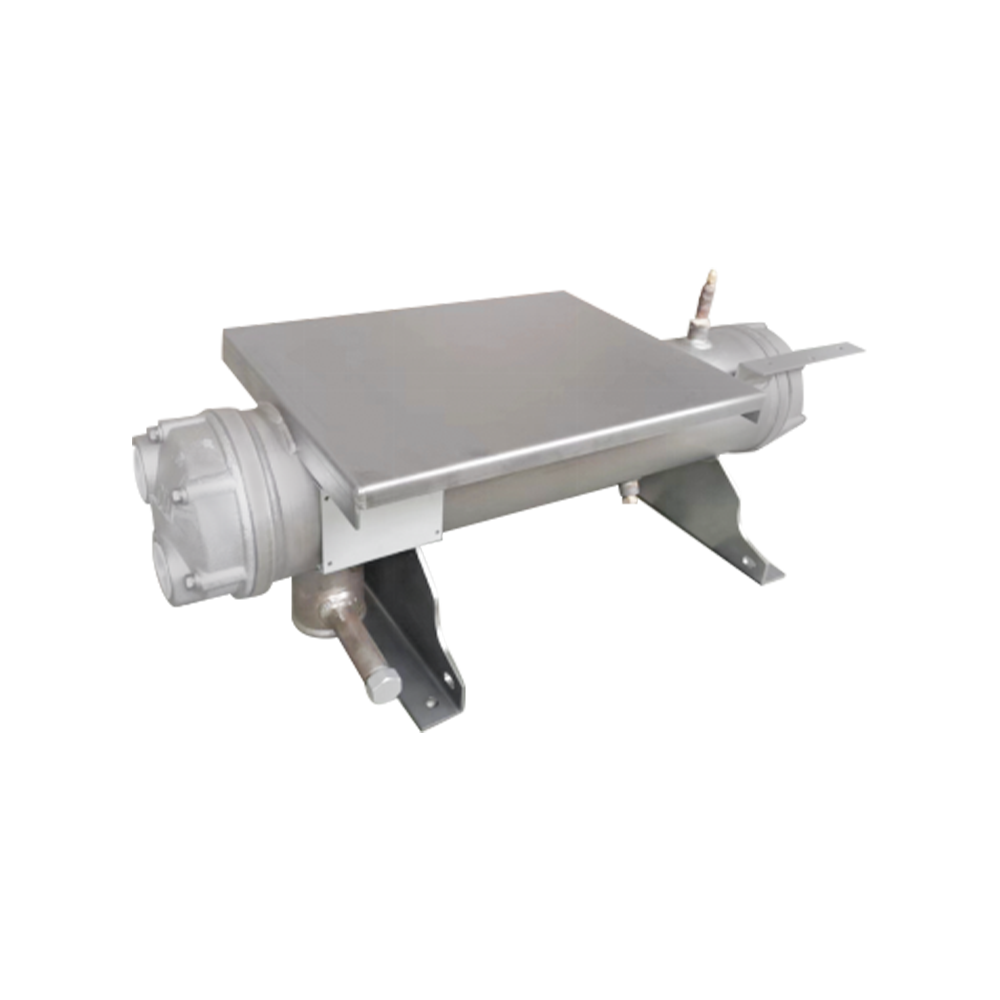

In the realm of industrial refrigeration and HVAC systems, the efficiency of heat rejection determines the overall performance and energy consumption of the entire plant. The KCWS series shell and tube water-cooled condenser stands out as a primary component designed to handle intensive thermal loads. These units are engineered to facilitate the phase change of refrigerants from gas to liquid by transferring heat to circulating water, a process that requires precision engineering to ensure maximum heat flux. Whether utilized in commercial cold storage or large-scale industrial processing, selecting a condenser with a broad capacity range—specifically between 8.3KW and 397.3KW—allows engineers to scale their cooling solutions effectively.

Choosing the right condenser involves more than just matching kilowatt ratings; it requires an understanding of fluid dynamics and material compatibility. The KCWS series is developed to support a versatile array of refrigerants, including R134a, R404A, R507, R407C, and R22. This multi-refrigerant compatibility ensures that facilities can transition to more environmentally friendly options or maintain existing systems without needing to replace core pressure vessels, providing a future-proof investment for facility managers.

Adherence to Rigorous Safety and Manufacturing Standards

Safety is the paramount concern when dealing with high-pressure refrigeration equipment. The KCWS series is manufactured under the strict oversight of the Technical Supervision Bureau, ensuring that every unit delivered to a job site meets or exceeds national safety mandates. By adhering to established codes, these condensers minimize the risk of catastrophic failure and ensure long-term structural integrity under fluctuating pressure cycles.

The following table outlines the specific regulatory frameworks that govern the design and inspection of the KCWS series:

| Standard Code | Description of Regulation | Application Area |

|---|---|---|

| GB150.1~GB150.4-2011 | General Pressure Vessel Design | Structural Integrity & Materials |

| GB151-2014 | Heat Exchanger Standards | Thermal Performance & Geometry |

| NB/T47012-2020 | Refrigeration Pressure Vessels | Refrigerant-Specific Requirements |

Versatility Across Different Environmental Conditions

One of the most frequent questions from procurement officers is whether a standard water-cooled condenser can withstand harsh environments, such as coastal regions or maritime applications. The KCWS series addresses this by offering specialized variants, including seawater-resistant condensers. These units utilize corrosion-resistant alloys and enhanced coating technologies to prevent the salt-induced degradation typically seen in standard copper-tubed heat exchangers.

Optimizing Heat Exchange Capacity

Performance optimization is achieved through internal tube geometry. By utilizing high-efficiency threaded tubes, the KCWS series increases the turbulence of the water flow, which breaks the boundary layer and enhances the heat transfer coefficient. This technical design allows for a more compact shell size while maintaining a massive 397.3KW capacity, saving valuable mechanical room space.

Key benefits of the KCWS design include:

- Low pressure drop on the water side, reducing pumping energy costs.

- High fouling resistance due to optimized water velocity within the tubes.

- Removable end covers for straightforward mechanical cleaning and inspection.

Maintenance Best Practices for Longevity and Safety

Even the most robust pressure vessels require a systematic maintenance schedule to prevent the gradual buildup of scale and biofilm. For water-cooled systems, water quality is the single most important factor. Hard water can lead to calcium deposits that act as insulators, significantly reducing the heat exchange efficiency and forcing the compressor to work harder, which increases electrical consumption by up to 15-20%.

To maintain the KCWS series at peak performance, follow these operational guidelines:

- Monitor the approach temperature—the difference between the leaving water temperature and the refrigerant condensing temperature. An increase of more than 2°C usually indicates fouling.

- Conduct annual eddy current testing on the tubes to detect any wall thinning or pitting corrosion before leaks occur.

- Ensure that the water treatment system is maintaining the correct pH levels and biocide concentrations to prevent microbiological growth.

- Verify that all safety relief valves are inspected and recertified according to local pressure vessel regulations every 12 to 24 months.

By integrating these safety standards and maintenance protocols, the KCWS series shell and tube water-cooled condensers provide a reliable, high-performance solution for any refrigeration challenge, balancing raw power with sophisticated engineering safety.

English

English 中文简体

中文简体