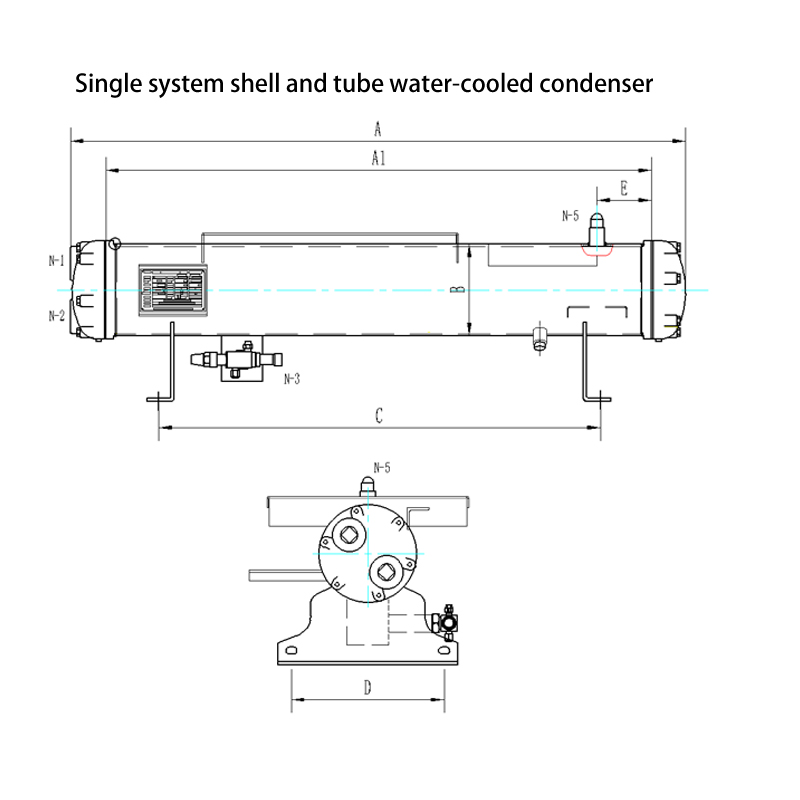

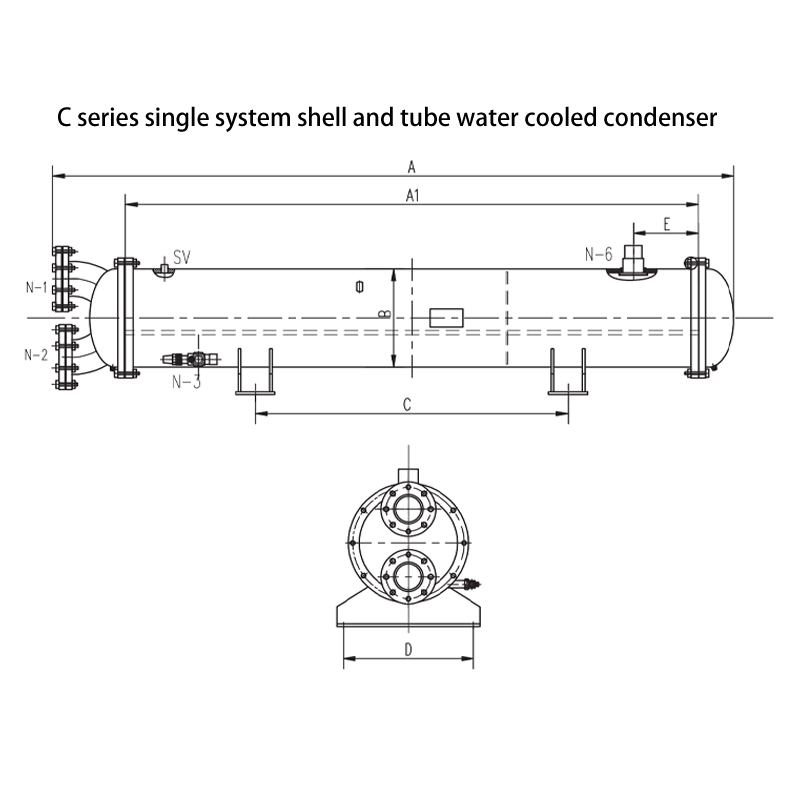

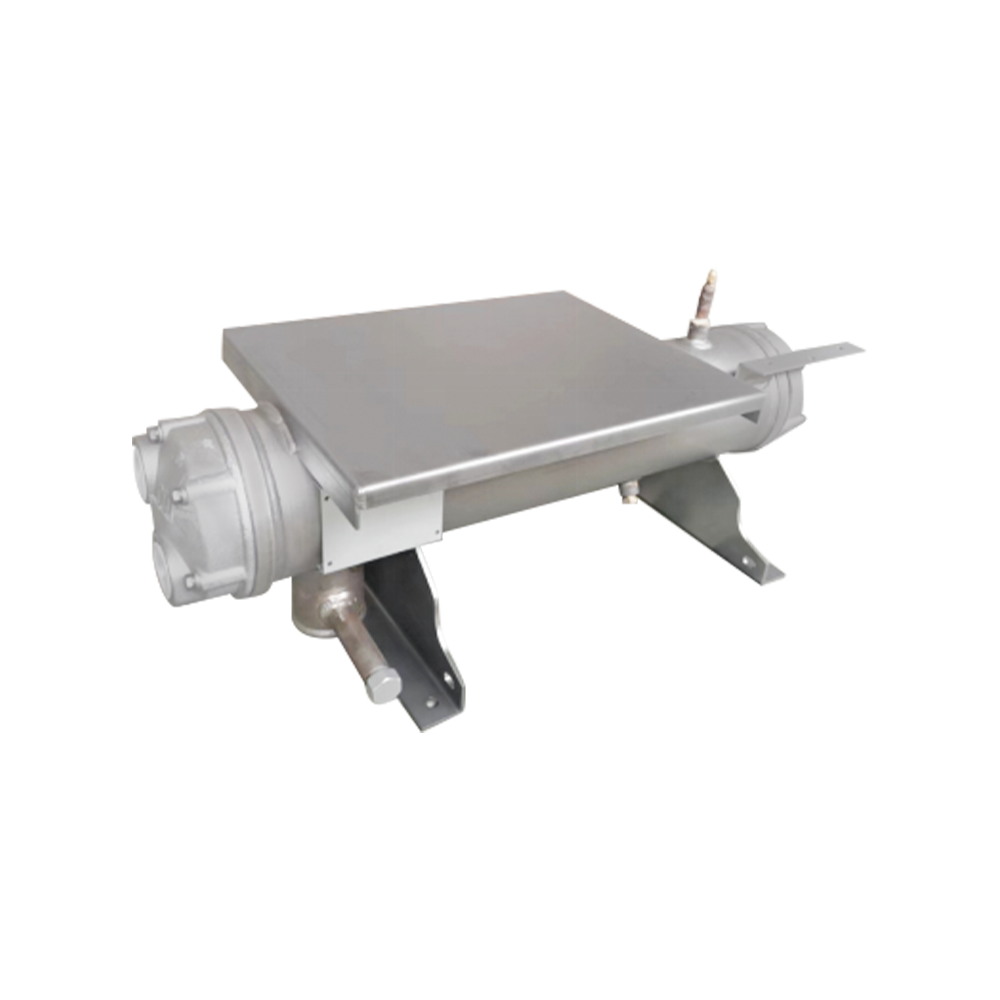

As an important pressure vessel product in the KCWS series, KCWS series shell and tube water cooled condenser strictly follows relevant national standards and industry standards such as GB150.1~GB150.4-2011 "Pressure Vessel", GB151-2014 "Heat Exchanger", NB/T47012-2020 "Pressure Vessel for Refrigeration Equipment", etc. Every link from design, material selection, manufacturing to factory inspection is completed under the supervision and inspection of the Technical Supervision Bureau to ensure that users can use it with peace of mind. This series includes shell and tube water-cooled condensers, seawater condensers and other types, with heat exchange ranging from 8.3KW to 397.3KW, suitable for various refrigerants such as R134a, R404A, R507, R407C, R22, etc., and can meet the refrigeration and heat exchange needs of different scenarios.

Product Features

1. Enhanced heat transfer:

The double-sided enhanced high-efficiency heat transfer copper tube is adopted, and the new special tooth shape of Kaidi condenser is developed in cooperation with the supplier, which significantly improves the heat exchange efficiency, makes the heat transfer faster and more sufficient, and helps to reduce the size of the equipment while ensuring the heat exchange.

2. Flexible adaptation:

The standardized design is adopted, and customization is supported according to the specific needs of customers, which can better fit different installation environments and usage scenarios. The inlet and outlet water interfaces adopt the left and right eccentric design, and are national standard threaded interfaces, which greatly facilitates the installation of customer-site pipelines and valves and reduces the tedious procedures during the installation process.

3. Stable operation:

The unique liquid collection bag design can better adapt to the fluctuation of the refrigerant in the cylinder, provide a more stable liquid supply effect for the system, and enhance the stability of the unit operation. The tube hole of the tube sheet adopts a multi-channel sealing groove design, which greatly reduces the risk of leakage between the tube sheet and the heat exchange tube, and further improves the reliability of the equipment.

4. Easy installation:

The standard compressor bracket, pressure gauge and oil separator bracket provide convenience for customers' installation work, saving installation time and cost.

5. Safety and comprehensiveness:

A "safety fusible plug" device is set. When the liquid temperature in the shell exceeds the set value, it will automatically melt and reduce the pressure to ensure the safety of the refrigeration system; there are drainage ports at the bottom of the front and rear covers to facilitate customers to drain water and avoid ice accumulation in the tube due to low ambient temperature, which may freeze the heat exchange tubes; all products have been tested for shell and tube pressure and passed the pressure maintenance test to eliminate leakage hazards from the source.

6. Excellent performance:

After secondary shot peening, the cleanliness of the shell is ensured, and the paint can be firmly attached, making the product beautiful. The overall size is small, the heat exchange capacity is large, and the failure rate is low, which can maintain good performance in long-term use.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026