Understanding Piston Compression Technology in Modern Cooling Systems

Commercial refrigeration has evolved significantly over the years, with various compressor technologies emerging to meet different industry needs. Among these options, piston-based compressors continue to hold a prominent position in the market due to their proven reliability and adaptability across diverse applications. The KU Series Piston Condensing Unit exemplifies how piston compression technology can be effectively implemented in commercial cooling equipment. This type of condensing unit leverages the fundamental principles of reciprocating motion to achieve refrigerant compression, a method that has been refined over decades of industrial application.

How Piston Compressors Function

At the core of piston-based compression technology is a straightforward mechanical process. The compressor contains a cylinder with a piston that moves back and forth, creating changes in pressure that facilitate the movement and compression of refrigerant. This reciprocating action enables efficient heat exchange and temperature regulation within the refrigeration system. The precision of the piston’s movement is crucial for maintaining consistent cooling performance. Unlike some other compression technologies that rely on continuous rotation, piston compressors operate through distinct strokes—intake and compression—which allows for controlled refrigerant handling and energy consumption.

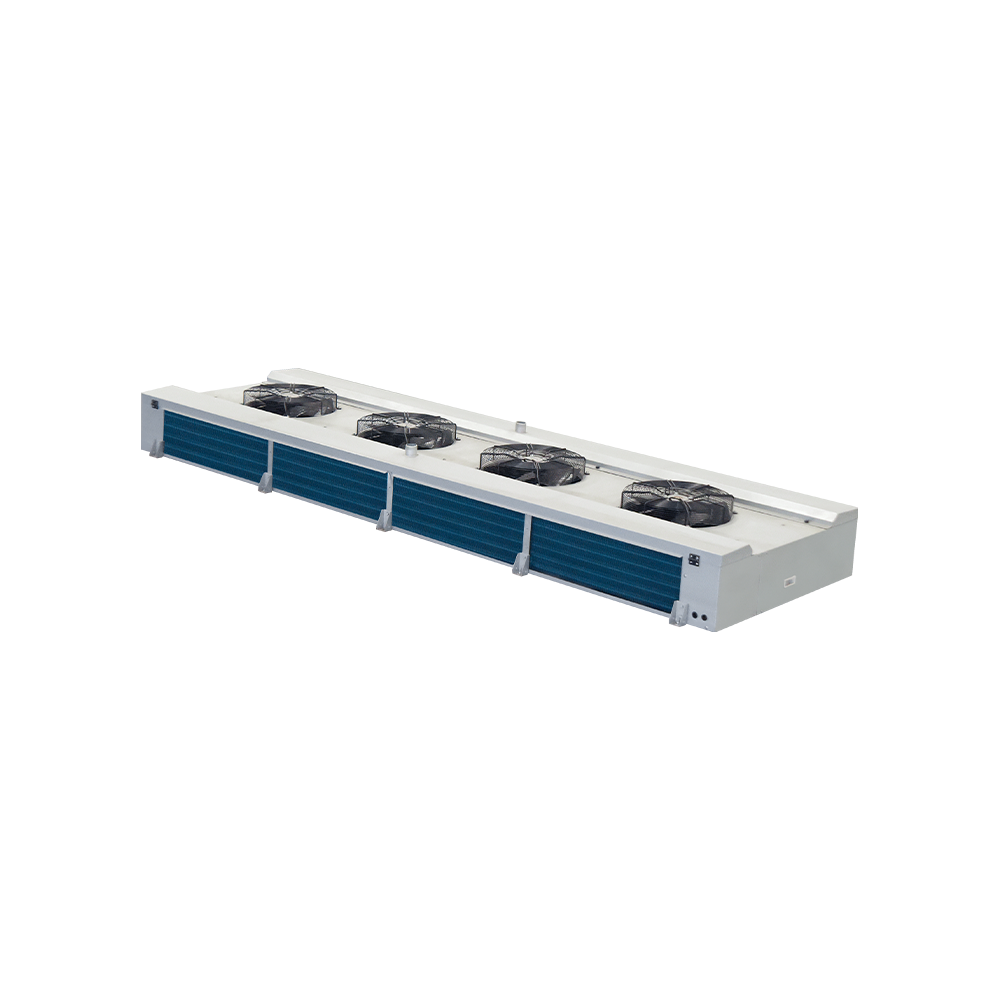

Box-Type Structure Design Benefits

Modern condensing units often incorporate box-type enclosures that offer several practical advantages. This design approach helps maintain a compact appearance while housing essential components in a organized manner. The box structure protects internal parts from environmental factors and simplifies installation in various commercial settings. The enclosed design also contributes to noise reduction, which is an important consideration for commercial environments where customer comfort is a priority. Additionally, the compact form factor allows for flexible placement options, making it easier to integrate the unit into existing refrigeration setups.

Comparing Piston Compressors with Other Technologies

When selecting commercial refrigeration equipment, understanding the differences between compressor technologies can help business owners make informed decisions. The following table outlines key characteristics of common compressor types used in commercial cooling applications.

| Compressor Type | Operating Principle | Common Applications | Key Characteristics |

|---|---|---|---|

| Piston | Reciprocating motion | Small to medium cold storage, commercial refrigerators | Proven reliability, flexible adaptability, efficient compression |

| Scroll | Orbiting spiral motion | Moderate temperature applications, air conditioning | Quiet operation, fewer moving parts |

| Screw | Rotating intermeshing screws | Large industrial cooling systems | High capacity, continuous operation |

| Centrifugal | High-speed impeller rotation | Large-scale air conditioning, industrial cooling | Very high capacity, efficient at full load |

Advantages of Piston-Based Systems

Piston compressors offer several benefits that make them suitable for specific commercial refrigeration needs. One notable advantage is their ability to handle varying load conditions effectively. Commercial environments often experience fluctuations in cooling demand, and piston compressors can adjust to these changes without significant performance degradation. Another benefit relates to maintenance considerations. The mechanical design of piston compressors is well-understood by technicians across the industry, which means that service and repair work can be performed with relative ease. This accessibility contributes to reduced downtime and lower long-term maintenance costs for businesses.

Application Scenarios for Piston Condensing Units

Commercial refrigeration encompasses a wide range of applications, each with unique requirements. Piston-based condensing units are particularly well-suited for certain scenarios where their characteristics align with operational needs.

Small to Medium Cold Storage Facilities

Cold storage facilities of moderate size often require consistent cooling performance without the extreme capacity demands of industrial-scale operations. The KU Series Piston Condensing Unit provides reliable power for such applications, maintaining appropriate temperature levels for stored goods throughout the day. These facilities benefit from the unit’s ability to deliver stable performance over extended periods. The continuous nature of cold storage operations aligns well with the operational characteristics of piston compressors, which can maintain consistent cooling output without significant variations.

Commercial Refrigeration Equipment

Restaurants, supermarkets, and convenience stores utilize various types of refrigeration equipment that operate intermittently rather than continuously. Display refrigerators, walk-in coolers, and freezers cycle on and off based on temperature requirements, which places different demands on the cooling system. Piston condensing units demonstrate good adaptability to these intermittent operating conditions. The design allows the compressor to start and stop efficiently without excessive wear, contributing to extended equipment lifespan and reliable service in commercial environments.

Key Performance Characteristics

When evaluating commercial refrigeration equipment, several performance factors warrant consideration. The following table summarizes important characteristics to assess when selecting a condensing unit for commercial applications.

| Performance Factor | Description | Importance for Commercial Use |

|---|---|---|

| Energy Efficiency | Ratio of cooling output to energy input | Impacts operating costs and environmental footprint |

| Durability | Ability to withstand operational stress | Affects maintenance frequency and replacement costs |

| Reliability | Consistency of performance over time | Ensures product quality and business continuity |

| Adaptability | Capacity to handle varying conditions | Accommodates changing business needs and load variations |

| Noise Level | Acoustic output during operation | Influences customer and employee comfort |

Efficiency Considerations

Energy consumption represents a significant operational cost for commercial refrigeration systems. Modern piston condensing units incorporate design features that aim to balance cooling effectiveness with reasonable energy usage. The precise reciprocating motion of the piston compressor enables efficient refrigerant compression, helping to minimize unnecessary energy expenditure. Business owners should consider both the initial investment and long-term operating costs when selecting refrigeration equipment. While piston compressors may not represent the newest technology on the market, their proven track record and reliable efficiency continue to make them a practical choice for many commercial applications.

Durability and Longevity

Commercial environments demand equipment that can withstand continuous use without frequent breakdowns. The robust construction of piston-based condensing units contributes to their ability to provide extended service life under demanding conditions. Regular maintenance plays an important role in preserving equipment performance and extending operational lifespan. The straightforward design of piston compressors facilitates routine servicing, helping to prevent minor issues from developing into major problems that could disrupt business operations.

Selection Guidelines for Commercial Applications

Choosing the appropriate condensing unit requires careful consideration of multiple factors. Business owners and facility managers should evaluate their specific cooling requirements before making a purchase decision.

Assessing Cooling Requirements

The first step in equipment selection involves determining the cooling capacity needed for the intended application. This assessment should consider factors such as the size of the space to be cooled, the temperature requirements for stored products, and the frequency of door openings or product loading. Small to medium-sized cold storage facilities and commercial refrigeration units typically fall within a specific capacity range that piston compressors can handle effectively. Understanding these requirements helps ensure that the selected equipment will meet operational needs without being oversized, which could lead to inefficient operation.

Installation and Space Considerations

The physical characteristics of the condensing unit influence where it can be installed and how much space it will occupy. Box-type designs offer advantages in terms of compactness and ease of placement, allowing for installation in various locations within a commercial facility. Adequate ventilation and accessibility for maintenance should also be factored into installation planning. The design of modern piston condensing units often incorporates features that simplify both initial installation and subsequent service work.

Industry Trends and Developments

The commercial refrigeration sector continues to evolve, with manufacturers implementing various improvements to enhance equipment performance and environmental compatibility. These developments aim to address changing market demands and regulatory requirements.

Environmental Considerations

Environmental regulations have prompted changes in refrigerant choices and equipment design across the industry. Modern piston condensing units are engineered to work with newer refrigerant formulations that have reduced environmental impact compared to older options. Manufacturers continue to refine compressor designs to improve efficiency while meeting increasingly stringent environmental standards. These efforts help businesses maintain compliance with regulations while managing energy costs effectively.

Technology Integration

Advanced control systems and monitoring capabilities are becoming more common in commercial refrigeration equipment. These technologies enable better management of cooling operations, helping to optimize performance and identify potential issues before they cause disruptions. Piston-based condensing units are not exempt from these technological advancements. Modern units incorporate electronic controls and monitoring features that enhance operational efficiency and provide valuable diagnostic information.

Conclusion

Piston-based condensing units continue to serve as a practical choice for many commercial refrigeration applications. Their proven design, reliable performance, and adaptability to varying operating conditions make them suitable for small to medium cold storage facilities and commercial refrigeration equipment. The KU Series Piston Condensing Unit demonstrates how established technology can be effectively implemented to meet contemporary commercial refrigeration needs. By balancing efficiency, durability, and adaptability, this equipment provides businesses with a cooling solution that supports reliable operation. When selecting commercial refrigeration equipment, business owners should carefully evaluate their specific requirements and consider how different compressor technologies align with their operational needs. Understanding the characteristics and benefits of piston compressors helps inform this decision-making process and supports long-term equipment satisfaction. As the commercial refrigeration industry continues to evolve, piston-based systems will likely maintain their position as a valuable option for businesses seeking reliable, efficient cooling solutions. Their combination of proven technology and continued refinement ensures that they remain relevant in a changing market landscape.What Are the Main Advantages of Piston Compressors in Commercial Refrigeration?

Understanding Piston Compression Technology in Modern Cooling Systems

Commercial refrigeration has evolved significantly over the years, with various compressor technologies emerging to meet different industry needs. Among these options, piston-based compressors continue to hold a prominent position in the market due to their proven reliability and adaptability across diverse applications. The KU Series Piston Condensing Unit exemplifies how piston compression technology can be effectively implemented in commercial cooling equipment. This type of condensing unit leverages the fundamental principles of reciprocating motion to achieve refrigerant compression, a method that has been refined over decades of industrial application.

How Piston Compressors Function

At the core of piston-based compression technology is a straightforward mechanical process. The compressor contains a cylinder with a piston that moves back and forth, creating changes in pressure that facilitate the movement and compression of refrigerant. This reciprocating action enables efficient heat exchange and temperature regulation within the refrigeration system. The precision of the piston’s movement is crucial for maintaining consistent cooling performance. Unlike some other compression technologies that rely on continuous rotation, piston compressors operate through distinct strokes—intake and compression—which allows for controlled refrigerant handling and energy consumption.

Box-Type Structure Design Benefits

Modern condensing units often incorporate box-type enclosures that offer several practical advantages. This design approach helps maintain a compact appearance while housing essential components in an organized manner. The box structure protects internal parts from environmental factors and simplifies installation in various commercial settings. The enclosed design also contributes to noise reduction, which is an important consideration for commercial environments where customer comfort is a priority. Additionally, the compact form factor allows for flexible placement options, making it easier to integrate the unit into existing refrigeration setups.

Comparing Piston Compressors with Other Technologies

When selecting commercial refrigeration equipment, understanding the differences between compressor technologies can help business owners make informed decisions. The following table outlines key characteristics of common compressor types used in commercial cooling applications.

| Compressor Type | Operating Principle | Common Applications | Key Characteristics |

|---|---|---|---|

| Piston | Reciprocating motion | Small to medium cold storage, commercial refrigerators | Proven reliability, flexible adaptability, efficient compression |

| Scroll | Orbiting spiral motion | Moderate temperature applications, air conditioning | Quiet operation, fewer moving parts |

| Screw | Rotating intermeshing screws | Large industrial cooling systems | High capacity, continuous operation |

| Centrifugal | High-speed impeller rotation | Large-scale air conditioning, industrial cooling | Very high capacity, efficient at full load |

Advantages of Piston-Based Systems

Piston compressors offer several benefits that make them suitable for specific commercial refrigeration needs. One notable advantage is their ability to handle varying load conditions effectively. Commercial environments often experience fluctuations in cooling demand, and piston compressors can adjust to these changes without significant performance degradation. Another benefit relates to maintenance considerations. The mechanical design of piston compressors is well-understood by technicians across the industry, which means that service and repair work can be performed with relative ease. This accessibility contributes to reduced downtime and lower long-term maintenance costs for businesses.

Application Scenarios for Piston Condensing Units

Commercial refrigeration encompasses a wide range of applications, each with unique requirements. Piston-based condensing units are particularly well-suited for certain scenarios where their characteristics align with operational needs.

Small to Medium Cold Storage Facilities

Cold storage facilities of moderate size often require consistent cooling performance without the extreme capacity demands of industrial-scale operations. These units provide reliable power for such applications, maintaining appropriate temperature levels for stored goods throughout the day. These facilities benefit from the unit’s ability to deliver stable performance over extended periods. The continuous nature of cold storage operations aligns well with the operational characteristics of piston compressors, which can maintain consistent cooling output without significant variations.

Commercial Refrigeration Equipment

Restaurants, supermarkets, and convenience stores utilize various types of refrigeration equipment that operate intermittently rather than continuously. Display refrigerators, walk-in coolers, and freezers cycle on and off based on temperature requirements, which places different demands on the cooling system. Piston condensing units demonstrate good adaptability to these intermittent operating conditions. The design allows the compressor to start and stop efficiently without excessive wear, contributing to extended equipment lifespan and reliable service in commercial environments.

Key Performance Characteristics

When evaluating commercial refrigeration equipment, several performance factors warrant consideration. The following table summarizes important characteristics to assess when selecting a condensing unit for commercial applications.

| Performance Factor | Description | Importance for Commercial Use |

|---|---|---|

| Energy Efficiency | Ratio of cooling output to energy input | Impacts operating costs and environmental footprint |

| Durability | Ability to withstand operational stress | Affects maintenance frequency and replacement costs |

| Reliability | Consistency of performance over time | Ensures product quality and business continuity |

| Adaptability | Capacity to handle varying conditions | Accommodates changing business needs and load variations |

| Noise Level | Acoustic output during operation | Influences customer and employee comfort |

Efficiency Considerations

Energy consumption represents a significant operational cost for commercial refrigeration systems. Modern piston condensing units incorporate design features that aim to balance cooling effectiveness with reasonable energy usage. The precise reciprocating motion of the piston compressor enables efficient refrigerant compression, helping to minimize unnecessary energy expenditure. Business owners should consider both the initial investment and long-term operating costs when selecting refrigeration equipment. While piston compressors may not represent the newest technology on the market, their proven track record and reliable efficiency continue to make them a practical choice for many commercial applications.

Durability and Longevity

Commercial environments demand equipment that can withstand continuous use without frequent breakdowns. The robust construction of piston-based condensing units contributes to their ability to provide extended service life under demanding conditions. Regular maintenance plays an important role in preserving equipment performance and extending operational lifespan. The straightforward design of piston compressors facilitates routine servicing, helping to prevent minor issues from developing into major problems that could disrupt business operations.

Selection Guidelines for Commercial Applications

Choosing the appropriate condensing unit requires careful consideration of multiple factors. Business owners and facility managers should evaluate their specific cooling requirements before making a purchase decision.

Assessing Cooling Requirements

The first step in equipment selection involves determining the cooling capacity needed for the intended application. This assessment should consider factors such as the size of the space to be cooled, the temperature requirements for stored products, and the frequency of door openings or product loading. Small to medium-sized cold storage facilities and commercial refrigeration units typically fall within a specific capacity range that piston compressors can handle effectively. Understanding these requirements helps ensure that the selected equipment will meet operational needs without being oversized, which could lead to inefficient operation.

Installation and Space Considerations

The physical characteristics of the condensing unit influence where it can be installed and how much space it will occupy. Box-type designs offer advantages in terms of compactness and ease of placement, allowing for installation in various locations within a commercial facility. Adequate ventilation and accessibility for maintenance should also be factored into installation planning. The design of modern piston condensing units often incorporates features that simplify both initial installation and subsequent service work.

Industry Trends and Developments

The commercial refrigeration sector continues to evolve, with manufacturers implementing various improvements to enhance equipment performance and environmental compatibility. These developments aim to address changing market demands and regulatory requirements.

Environmental Considerations

Environmental regulations have prompted changes in refrigerant choices and equipment design across the industry. Modern piston condensing units are engineered to work with newer refrigerant formulations that have reduced environmental impact compared to older options. Manufacturers continue to refine compressor designs to improve efficiency while meeting increasingly stringent environmental standards. These efforts help businesses maintain compliance with regulations while managing energy costs effectively.

Technology Integration

Advanced control systems and monitoring capabilities are becoming more common in commercial refrigeration equipment. These technologies enable better management of cooling operations, helping to optimize performance and identify potential issues before they cause disruptions. Piston-based condensing units are not exempt from these technological advancements. Modern units incorporate electronic controls and monitoring features that enhance operational efficiency and provide valuable diagnostic information.

Conclusion

Piston-based condensing units continue to serve as a practical choice for many commercial refrigeration applications. Their proven design, reliable performance, and adaptability to varying operating conditions make them suitable for small to medium cold storage facilities and commercial refrigeration equipment. The KU Series Piston Condensing Unit demonstrates how established technology can be effectively implemented to meet contemporary commercial refrigeration needs. By balancing efficiency, durability, and adaptability, this equipment provides businesses with a cooling solution that supports reliable operation. When selecting commercial refrigeration equipment, business owners should carefully evaluate their specific requirements and consider how different compressor technologies align with their operational needs. Understanding the characteristics and benefits of piston compressors helps inform this decision-making process and supports long-term equipment satisfaction. As the commercial refrigeration industry continues to evolve, piston-based systems will likely maintain their position as a valuable option for businesses seeking reliable, efficient cooling solutions. Their combination of proven technology and continued refinement ensures that they remain relevant in a changing market landscape.

English

English 中文简体

中文简体