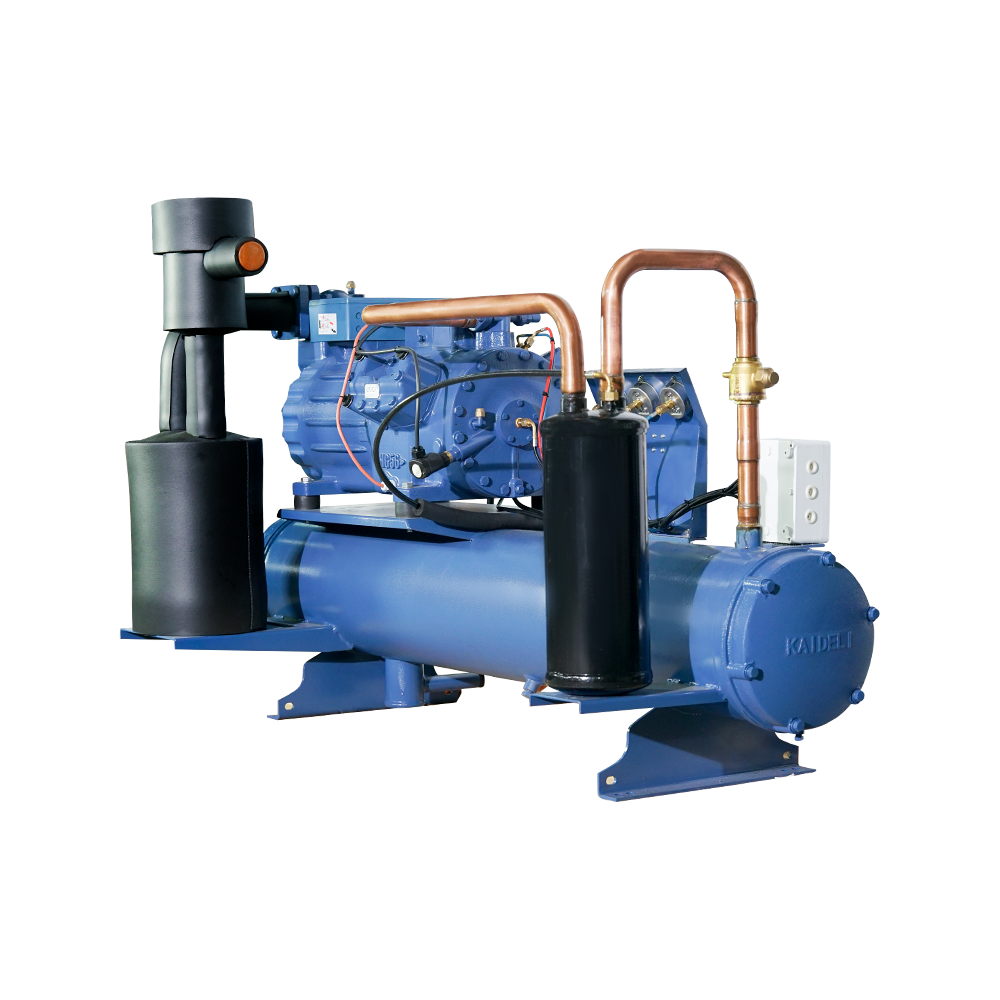

The Barrel Pump Condensing Unit is a highly efficient refrigerant delivery and control device designed for refrigeration systems. It integrates advanced pump bodies, liquid storage devices, control components and safety protection systems. Through scientific system design, it can achieve stable delivery, precise distribution and intelligent management of refrigerants. Whether it is a large cold storage group, a food freezing processing workshop, or a pharmaceutical cold chain storage, the unit can provide a solid guarantee for the efficient operation of the refrigeration system with its excellent performance, and meet the refrigerant supply needs under different scales and working conditions.

Product Features

1. Improve evaporation efficiency:

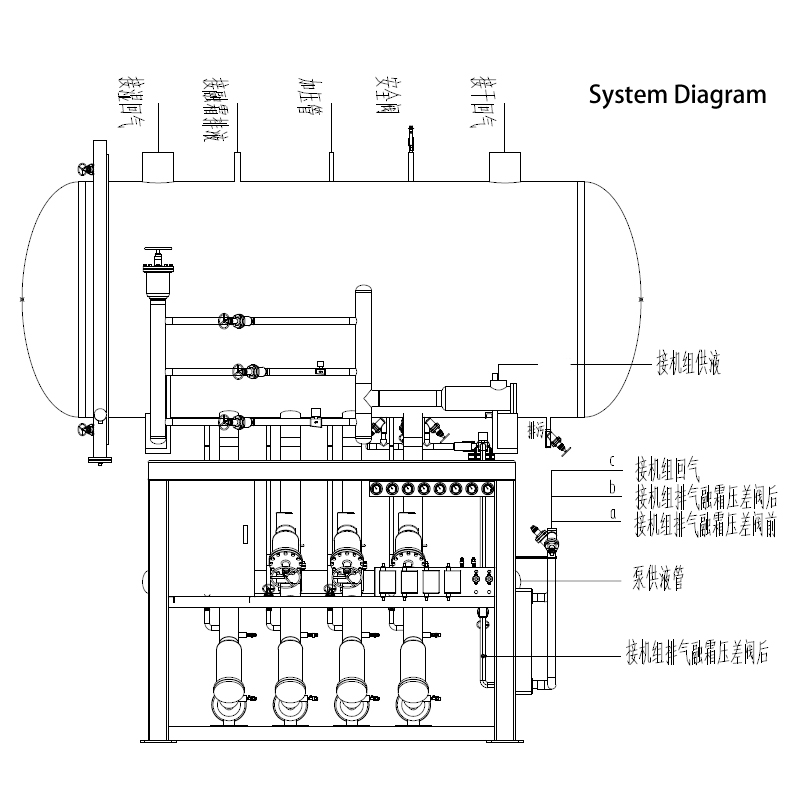

The pump forced liquid supply method is adopted. Compared with the traditional gravity liquid supply, the refrigerant can circulate in the evaporator at a higher flow rate, effectively flush the evaporator tube wall, reduce the adhesion and deposition of oil on the tube wall, and reduce the thermal resistance during the heat exchange process. This design significantly improves the heat exchange efficiency of the evaporator, thereby enhancing the refrigeration capacity of the entire refrigeration system, shortening the cooling time, and improving the stability of the refrigeration effect.

2. Adapt to complex working conditions:

With strong power performance and optimized pipeline design, it can easily cope with the challenges of long-distance transportation and liquid supply in cold storage with large height differences. Even in complex scenarios where cold storage is dispersed and the floor height difference is large, the refrigerant can flow evenly and stably between the evaporators, ensuring that each area can obtain sufficient refrigerant supply and maintain a stable refrigeration temperature without being restricted by the spatial layout.

3. Liquid level control:

Using high-precision liquid level control technology, sensitive sensors monitor the changes in the refrigerant level in the liquid storage tank in real time and feed the data back to the control system. The control system will automatically adjust the liquid intake according to the preset liquid level parameters to keep the liquid level in the liquid storage tank within the optimal range. This not only avoids refrigerant overflow caused by excessively high liquid level or idling of the pump body caused by too low liquid level, but also ensures the continuity and stability of liquid supply, providing a reliable basis for the normal operation of the system.

4. Oil return guarantee:

equipped with professional oil return structure and control logic, it can effectively separate the lubricating oil mixed with the refrigerant in the refrigeration system and guide the lubricating oil to flow back to the compressor smoothly. This technology ensures that key components such as the compressor are always fully and evenly lubricated, reduces mechanical wear, reduces the occurrence of failures, extends the service life of the equipment, and avoids the operating efficiency and safety of the compressor due to insufficient lubricating oil.

5. Safety protection:

It integrates multiple safety devices such as phase sequence protection, high and low liquid level protection, pump pressure difference protection, liquid cut-off protection, and overcurrent protection. Phase sequence protection can prevent the pump body from reversing due to incorrect power phase sequence; high and low liquid level protection can timely alarm and take measures when the liquid level in the storage tank is abnormal; pump pressure difference protection monitors the inlet and outlet pressure difference of the pump body to ensure the normal operation of the pump body; liquid cut-off protection can avoid damage to the pump body when it runs without liquid; overcurrent protection prevents the motor from burning due to excessive current. These protection functions monitor the operating status of the unit in all directions, respond quickly when abnormal conditions occur, ensure the safe and reliable operation of the unit, and reduce the risk of equipment damage and production interruption.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026