KU series scroll condensing unit is a refrigeration equipment that combines high efficiency and convenience. The overall box structure is not only compact and beautiful, but also realizes uniform wind field through reasonable design, fully releases the heat exchange capacity of the condenser, and leads the industry in energy efficiency. Equipped with an external rotor motor, the fan has low operating noise, and the panel is easy to disassemble and convenient for maintenance. Relying on good cooperation with suppliers, the quality of raw materials is stable to ensure product quality.

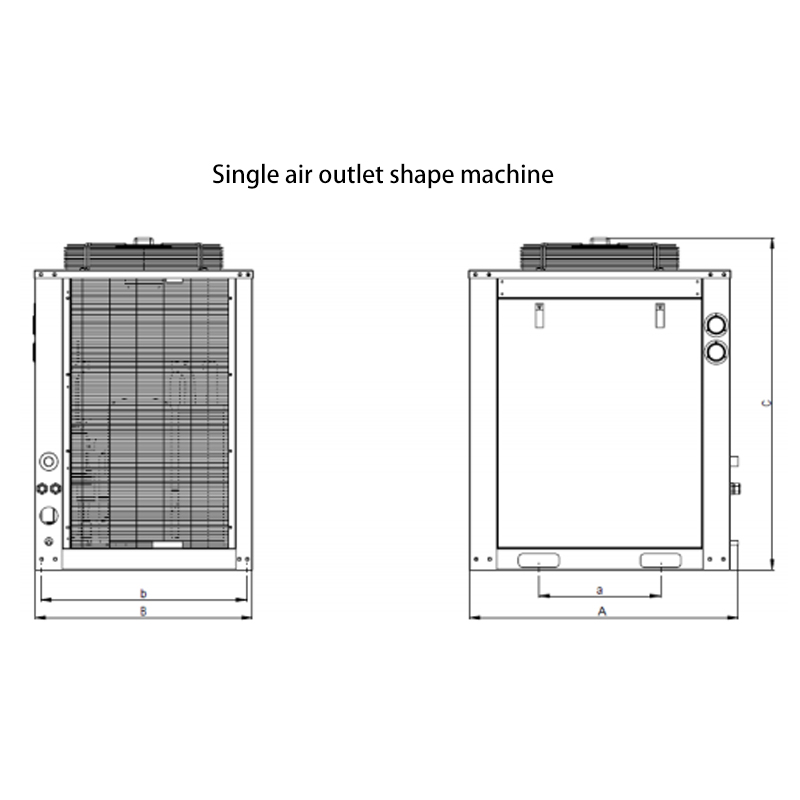

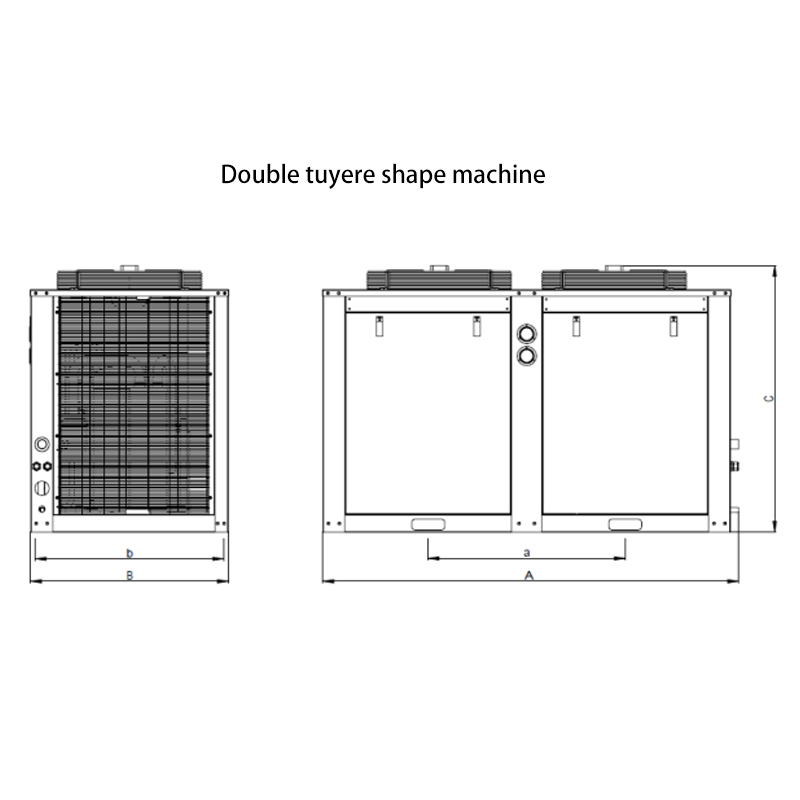

1. Integrated box structure:

The fully enclosed box frame is adopted to integrate the compressor, condenser, and electronic control system into the IP54 protection grade housing to achieve modular installation. The box air duct is optimized by CFD fluid simulation, and the air side resistance is reduced by 18%. Combined with the bionic air duct design, the heat exchange efficiency of the condenser is increased by 12%.

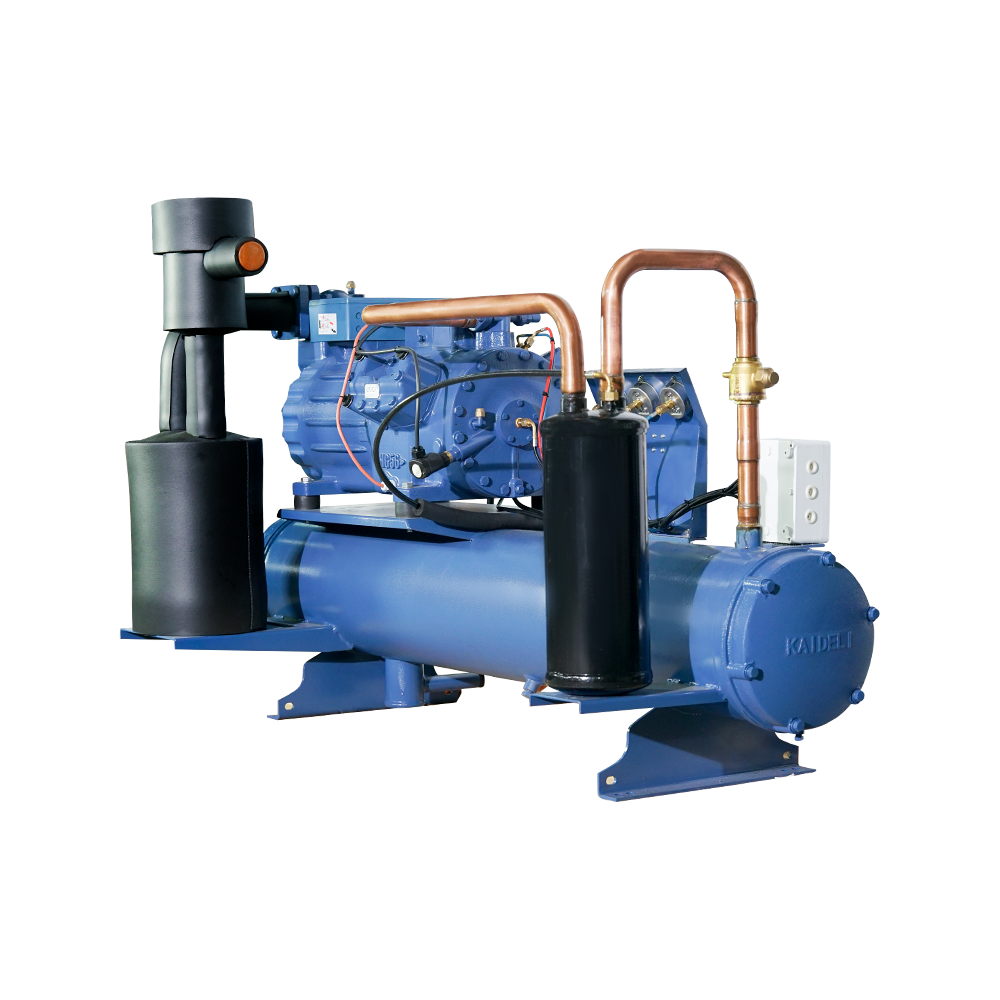

2. Application of scroll compression technology:

Compatible with Copeland ZBKN medium and high temperature series and ZFIKN low temperature series scroll compressors, it adopts a double flexible scroll disk design, and through the dynamic compensation technology of radial and axial gaps, the volumetric efficiency reaches more than 95%. Low-temperature models are equipped with EVI technology as standard, which increases heating capacity by 25% at -25℃, and improves energy efficiency by 20% compared to traditional liquid spray cooling solutions.

3. Multi-media adaptability:

Supports R134a (high temperature), R404A/R507 (medium and low temperature) and R448A/R449A (low GWP refrigerants), which can adapt to different temperature zone requirements. The system design is compatible with mineral oil and POE ester lubricants, and passes the oil separation efficiency test (≥99.8%) to ensure reliable oil return of the compressor.

4. Refrigerant charging solution:

Adopting a pre-charged refrigerant design, the R448A model has a 15% reduction in charging volume compared to R404A, which meets the requirements of EU F-gas regulations. Reserve future refrigerant replacement interfaces to support fluorine-free transformation of R22 systems.

5. Quiet and reliable:

The external rotor fan is combined with the bionic air duct design, and the operating noise is ≤68dB (A), which is 5-8dB lower than similar products and meets the night operation requirements of residential areas. The condenser uses hydrophilic aluminum foil and corrosion-resistant copper tubes, passed the salt spray test (500 hours without rust), and is suitable for coastal high humidity environments. The compressor has a built-in pressure relief valve and exhaust temperature protection, combined with multiple safety interlocks (high and low pressure switches, motor overload protection), to ensure continuous operation for 100,000 hours without failure.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026