Understanding Modern Refrigeration Requirements

As cold storage facilities continue to expand across various industries, selecting the appropriate condensing unit has become a critical decision for business owners and facility managers. The refrigeration landscape has evolved significantly, with new technologies offering enhanced efficiency and reliability. Among these innovations, the Box Type Condensing Unit has gained attention for its compact design and reliable performance.

The Importance of Proper Temperature Control

Temperature control stands as one of the essential factors in cold storage operations. Different applications require varying temperature ranges, from fruit and vegetable preservation to meat freezing and pharmaceutical warehousing. Modern condensing units now offer flexible temperature capabilities that can accommodate these diverse needs. The temperature coverage range of advanced systems typically extends from +15°C to -35°C, enabling facilities to handle multiple types of products within a single installation. This versatility allows businesses to adapt their cold storage capabilities based on seasonal demands or changing inventory requirements.

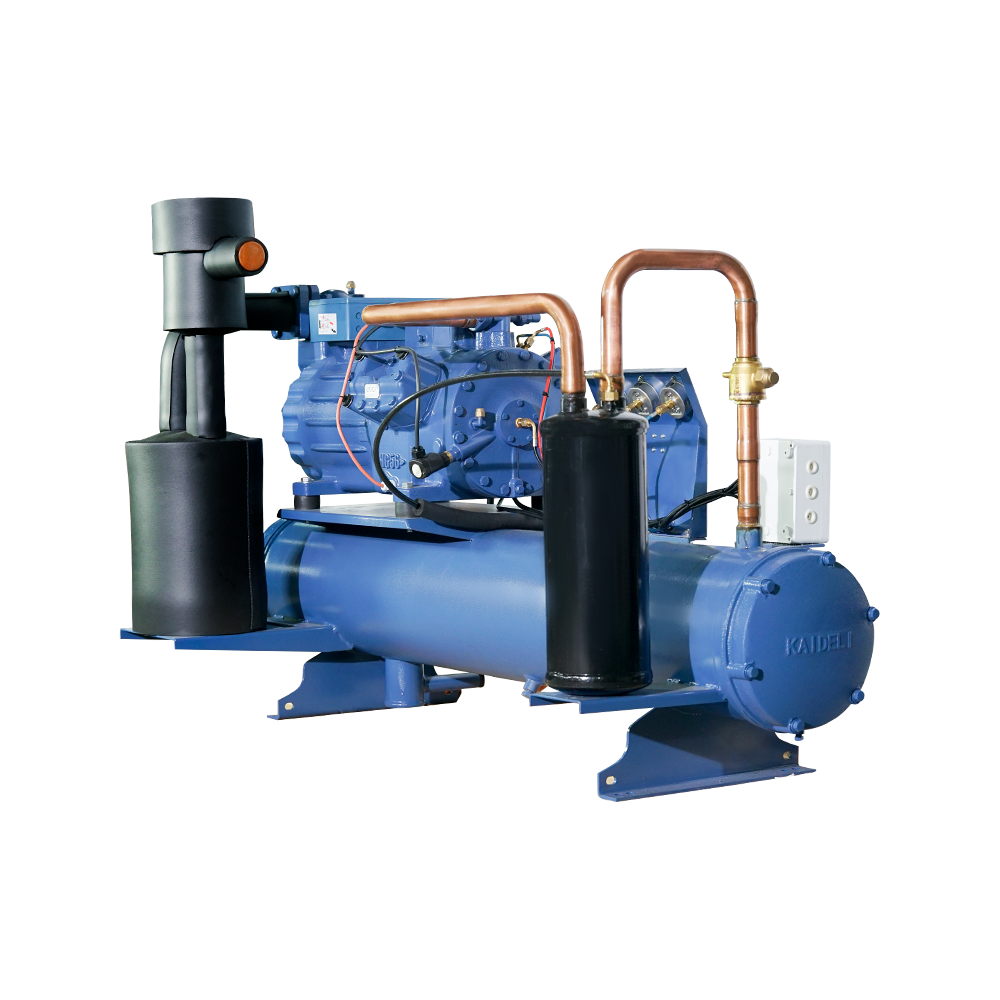

Key Components That Define Performance

When evaluating condensing units, several technical specifications deserve careful consideration. The compressor serves as the heart of any refrigeration system, and its quality directly impacts overall performance. High-quality compressors from reputable manufacturers can significantly enhance reliability and energy efficiency. Other critical components include the condenser design, fan systems, and electrical integration. These elements work together to determine the unit’s heat exchange capabilities, noise levels, and ease of installation. The patented U-shaped condenser design, for instance, can deliver improved heat exchange efficiency compared to traditional configurations.

Space Efficiency and Installation Considerations

Modern cold storage facilities often face space constraints, making compact equipment designs increasingly valuable. The horizontal compact structure of contemporary condensing units helps maximize space utilization while maintaining accessibility for maintenance purposes.

Industrial-Grade Construction Standards

Durability represents another crucial factor, especially for units operating in outdoor environments. Industrial-grade protection designs typically feature thickened galvanized steel plates with specialized surface treatments to withstand harsh conditions. Units that pass extensive salt spray testing demonstrate their ability to maintain reliable operation over extended periods. The protective coating not only enhances corrosion resistance but also contributes to the unit’s aesthetic appearance. A silver-gray finish (RAL9006) provides professional appearance while resisting environmental degradation.

Noise Control in Sensitive Environments

Operating noise levels have become an important consideration, particularly for installations near residential areas or in mixed-use facilities. Advanced condensing units incorporate various noise reduction technologies to keep sound levels within acceptable ranges. Sound-absorbing materials, shock absorption devices, and optimized fan designs all contribute to quieter operation. Units that maintain noise levels below 65 decibels can help minimize disturbance to surrounding areas while maintaining efficient performance.

Performance Specifications and Technical Data

To help facility managers make informed decisions, the following tables present key technical specifications for different condensing unit configurations:

High Temperature Unit Specifications

| Unit Model | Power Supply | Applicable Temperature | Maximum Current (A) | Weight (kg) |

|---|---|---|---|---|

| BB05H | 3PH/380V/50Hz | 8℃~15℃ | 10.8 | 218 |

| BB06H | 3PH/380V/50Hz | 8℃~15℃ | 13.6 | 222 |

| BB07H | 3PH/380V/50Hz | 8℃~15℃ | 16.5 | 270 |

| BB09H | 3PH/380V/50Hz | 8℃~15℃ | 20.2 | 275 |

| BB12H | 3PH/380V/50Hz | 8℃~15℃ | 25.2 | 390 |

Medium Temperature Unit Specifications

| Unit Model | Power Supply | Applicable Temperature | Cooling Capacity (kW) at -5℃ | Power Consumption (kW) |

|---|---|---|---|---|

| BB05M | 3PH/380V/50Hz | -5℃~5℃ | 10.2 | 3.9 |

| BB06M | 3PH/380V/50Hz | -5℃~5℃ | 12.9 | 5.0 |

| BB07M | 3PH/380V/50Hz | -5℃~5℃ | 15.0 | 5.7 |

| BB09M | 3PH/380V/50Hz | -5℃~5℃ | 19.0 | 7.3 |

| BB12M | 3PH/380V/50Hz | -5℃~5℃ | 24.8 | 8.9 |

Low Temperature Unit Specifications

| Unit Model | Power Supply | Applicable Temperature | Cooling Capacity (kW) at -20℃ | Power Consumption (kW) |

|---|---|---|---|---|

| BB05L | 3PH/380V/50Hz | -15℃~-35℃ | 5.8 | 3.2 |

| BB06L | 3PH/380V/50Hz | -15℃~-35℃ | 7.2 | 4.0 |

| BB07L | 3PH/380V/50Hz | -15℃~-35℃ | 8.5 | 4.6 |

| BB09L | 3PH/380V/50Hz | -15℃~-35℃ | 10.9 | 5.8 |

| BB12L | 3PH/380V/50Hz | -15℃~-35℃ | 14.2 | 7.2 |

Installation and Maintenance Advantages

The efficiency of installation processes can significantly impact project timelines and overall costs. Innovative electrical integrated designs can reduce installation time substantially compared to traditional configurations. This efficiency gain helps facility managers complete projects more quickly and reduce labor expenses.

Accessibility for Regular Maintenance

Maintenance accessibility represents another important consideration for long-term operational efficiency. Quick-opening inspection doors and well-placed service points enable technicians to perform routine maintenance tasks with minimal disruption. Units designed with maintenance in mind typically experience less downtime over their operational lifespan. The modular box design approach allows for easier component access and replacement when necessary. This design philosophy helps reduce maintenance complexity and can extend equipment service life.

Energy Efficiency and Environmental Considerations

Energy consumption remains one of the significant operational expenses for cold storage facilities. Modern condensing units incorporate various technologies to enhance energy efficiency while maintaining cooling performance. High-efficiency oil separators, optimized valve plate designs, and intelligent control systems all contribute to reduced energy consumption.

Refrigerant Compatibility Options

Environmental regulations continue to evolve, requiring equipment that can accommodate different refrigerant types. Advanced condensing units typically offer compatibility with multiple refrigerant options, including R404A, R507A, R448A, R449A, and R22. This flexibility allows facility operators to adapt to changing regulatory requirements without replacing their entire refrigeration infrastructure.

Adaptability to Various Environmental Conditions

Outdoor installations must contend with varying ambient temperatures and weather conditions. Units designed to operate across a wide ambient temperature range can maintain consistent performance regardless of external conditions. This adaptability ensures reliable operation throughout the year, regardless of seasonal temperature variations.

Application Scenarios and Industry Suitability

Different industries have unique requirements for cold storage equipment. Understanding these specific needs helps facility managers select appropriate systems for their applications.

Fruit and Vegetable Preservation

Fresh produce requires precise temperature and humidity control to maintain quality and extend shelf life. High-temperature condensing units designed for applications between +8℃ and +15℃ provide ideal conditions for fruit and vegetable storage. These systems help reduce spoilage and maintain product freshness throughout the supply chain.

Meat and Poultry Freezing

Meat processing facilities require lower temperatures to ensure food safety and product quality. Medium and low temperature units capable of reaching -35℃ provide the necessary conditions for meat freezing and long-term storage. These systems help preserve product quality while meeting food safety regulations.

Pharmaceutical and Medical Storage

Pharmaceutical products often require precise temperature control to maintain efficacy. Cold storage facilities serving the healthcare industry need reliable equipment that can maintain consistent temperatures within narrow ranges. Modern condensing units with intelligent control capabilities can meet these demanding requirements.

Making the Right Investment Decision

Selecting a condensing unit involves balancing multiple factors including initial cost, operating efficiency, maintenance requirements, and expected service life. A thorough evaluation of these factors helps ensure that the selected equipment meets both current needs and future requirements.

Long-Term Value Considerations

While initial purchase price represents an important consideration, the total cost of ownership provides a more accurate picture of long-term value. Energy efficiency, maintenance requirements, and equipment durability all contribute to the overall economics of cold storage operations. Units that demonstrate proven reliability in various operating conditions typically deliver better long-term value, even if their initial cost is higher. The reduced downtime and maintenance expenses can offset higher purchase prices over time.

Conclusion

The selection of a condensing unit for cold storage applications requires careful consideration of multiple technical and operational factors. By understanding their specific requirements and evaluating available options systematically, facility managers can select equipment that delivers reliable performance while meeting their budget constraints. Modern Box Type Condensing Unit options continue to evolve, offering enhanced efficiency, reliability, and flexibility for diverse cold storage applications. Staying informed about technological advances and industry best practices helps facility managers make decisions that support their operational goals and business success. As the cold storage industry continues to grow and evolve, equipment selection will remain a critical factor in operational success. By partnering with reputable suppliers and choosing equipment based on comprehensive evaluations, facility managers can build reliable, efficient cold storage systems that serve their needs for years to come.

English

English 中文简体

中文简体