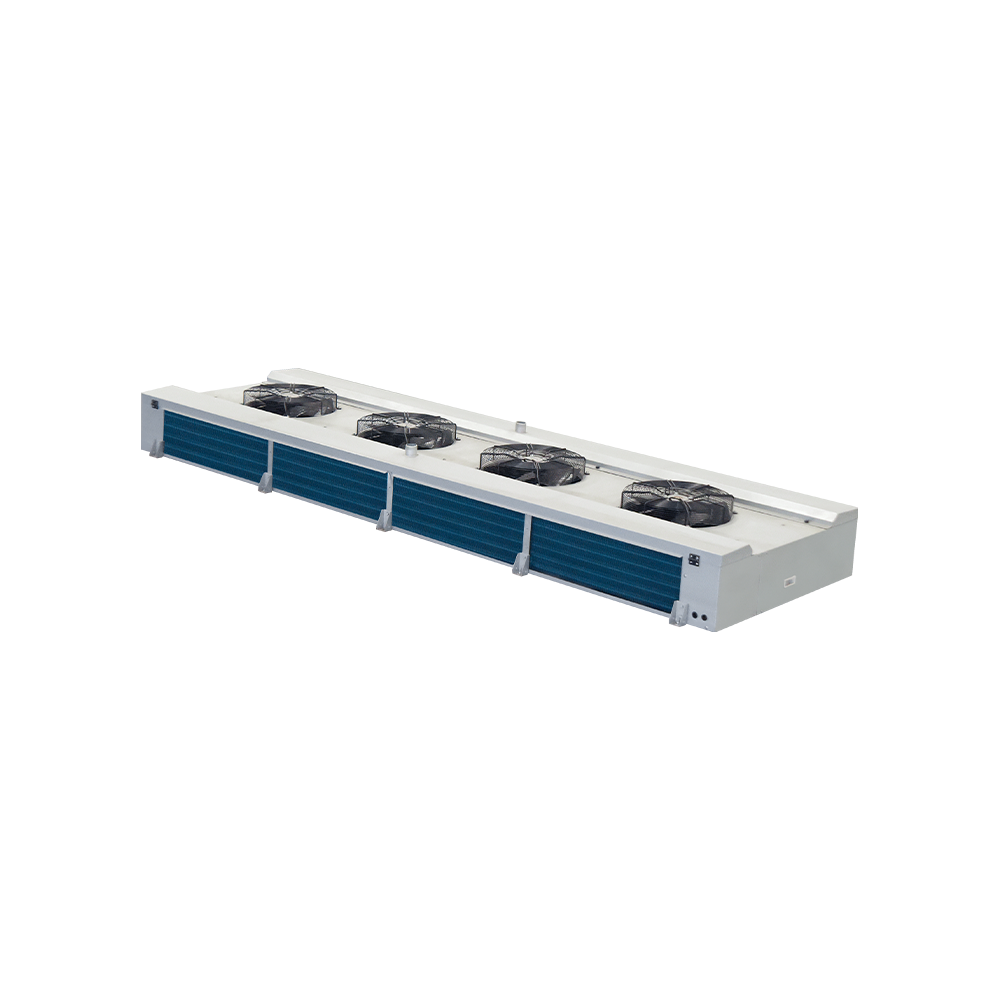

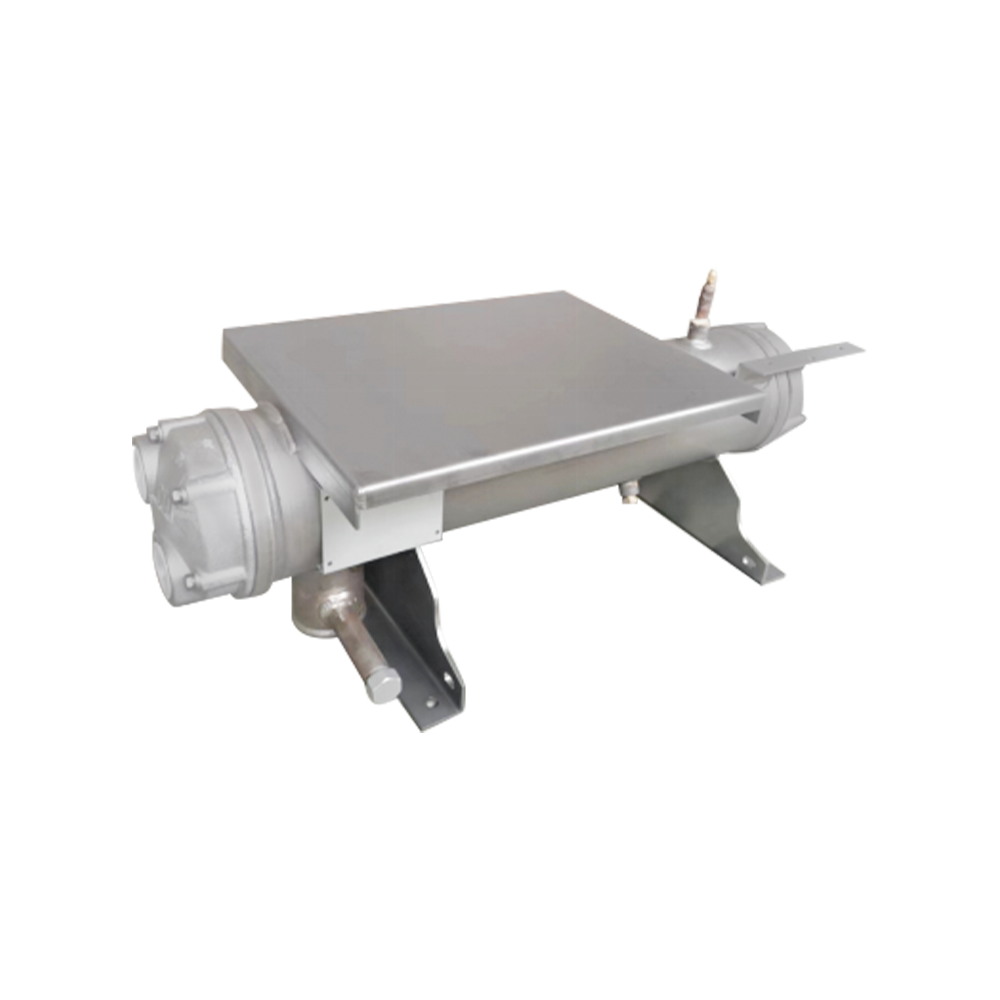

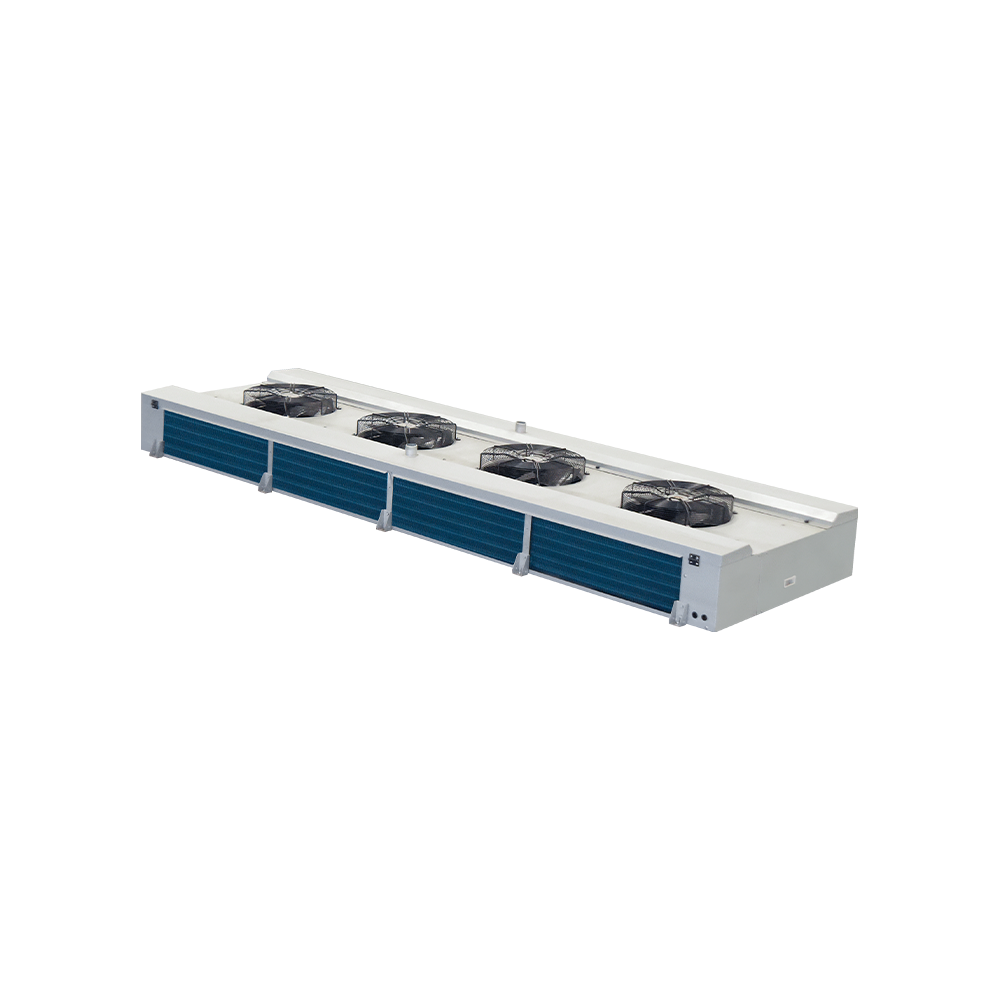

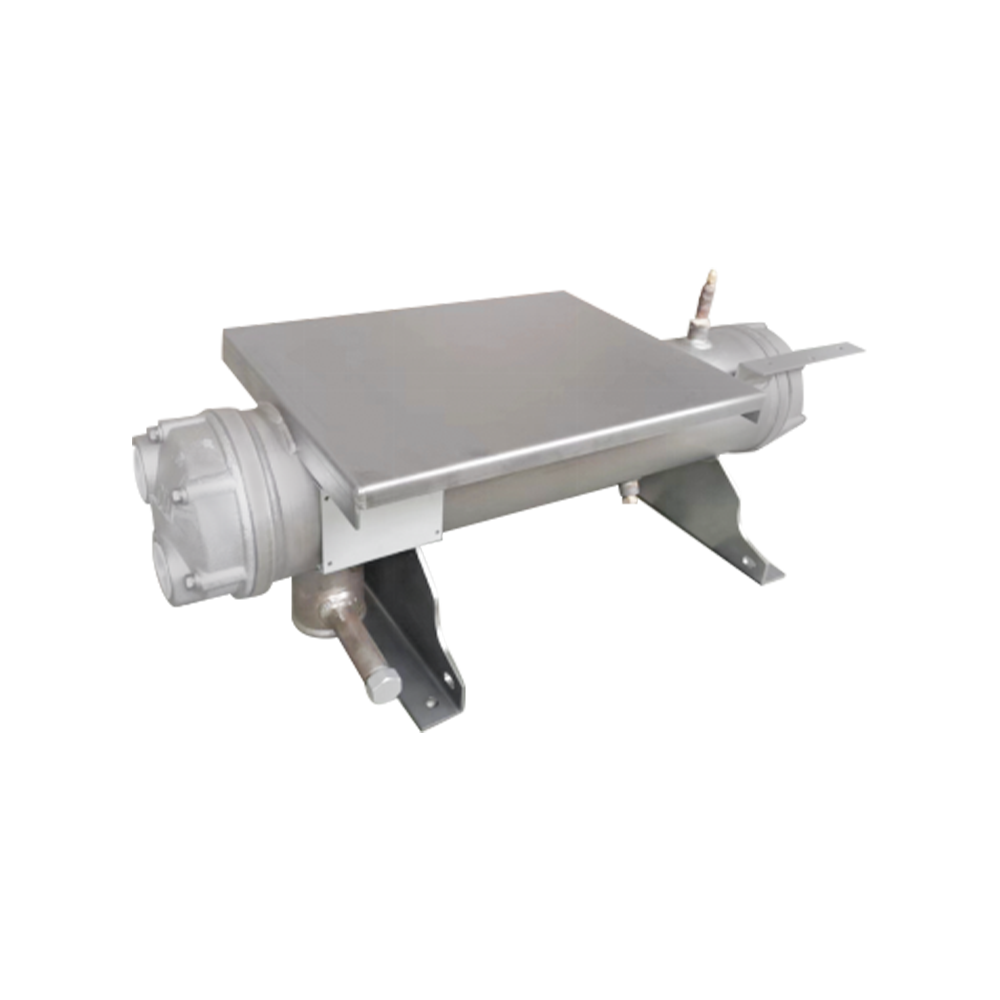

ESP series pump-fed liquid-fed stainless steel tube air cooler deeply adapts to the barrel pump liquid supply fluorine system and the CO₂ system with subcritical operation. It adopts an efficient pump liquid supply operation mechanism and has a strong pressure bearing performance of 52bar. The equipment shell is made of 304 stainless steel, paired with hinged side plates and outer water trays, for convenient operation; the double-layer water tray structure is innovative, the outer edge-angle structure ensures smooth drainage, and the inner aluminum plate sink design efficiently diverts condensate and defrost water to ensure the stable operation of the equipment.

In terms of performance, the coil structure arranged in square arrangement of φ15 stainless steel pipes is adopted to greatly improve heat transfer efficiency, effectively reduce food dry consumption, and significantly delay the frosting cycle of the fins. It is also equipped with hydrophilic aluminum foil corrugated aluminum sheets with multiple pitches, which can flexibly adapt to different temperature and humidity working conditions. The fan selection fully considers the application in multiple scenarios, with a wide temperature range of -30℃ to -40℃, providing reliable refrigeration guarantee for all kinds of low-temperature environments. The defrost system is flexible and diverse, with a standard electric heat defrost function, and also supports customized water frost solutions. In addition, the IP65 waterproof wiring design and independent wiring layout ensure all-round safety; the equipment supports a variety of refrigerants, showing excellent adaptability and compatibility.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026