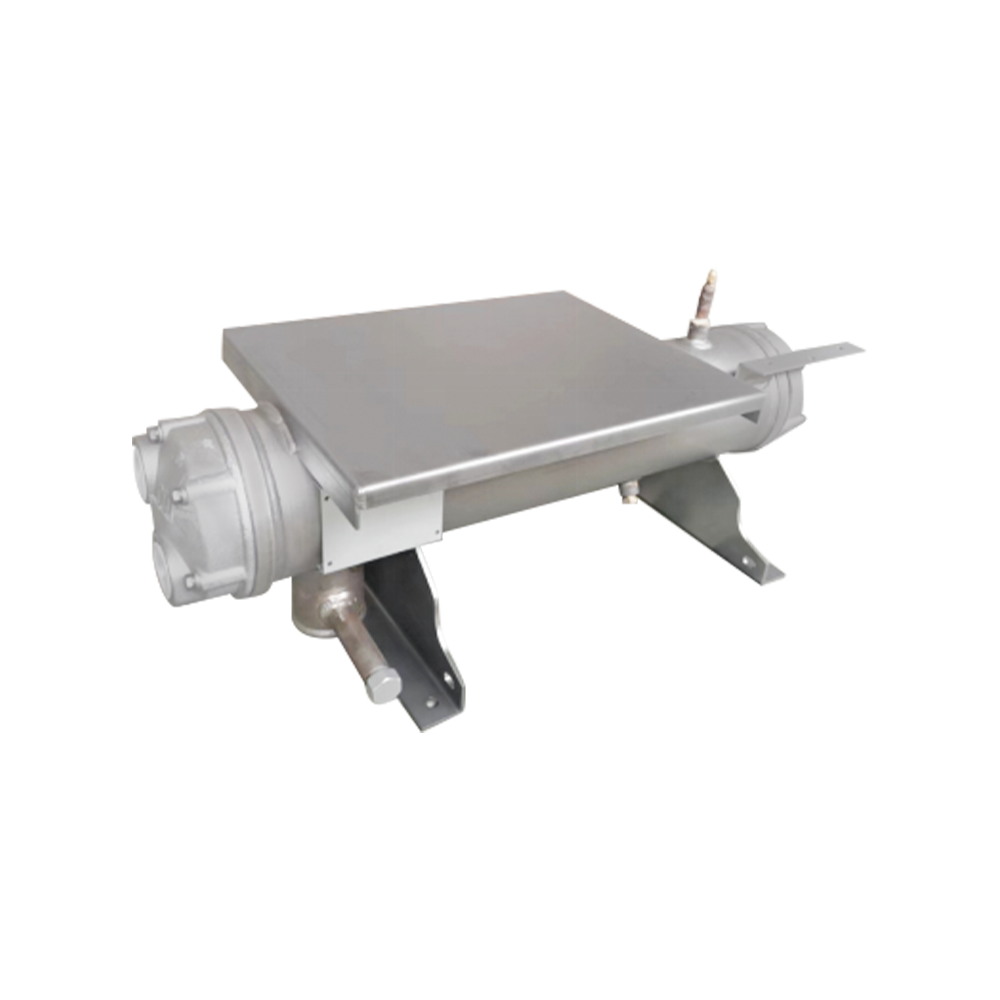

CL series vertical side mounted condenser is a professional refrigeration equipment carefully developed for the problem of split installation of air-cooled condenser units. In the field of modern industrial refrigeration, many scenarios need to be installed separately from the compressor due to space layout, equipment maintenance or functional partitioning. Traditional condensers are difficult to meet such special needs. The condenser innovatively adopts a vertical side-mounted structure, following the scientific air flow path of the air inlet behind and the air out in front, effectively solving the problems of heat dissipation and airflow organization during split installation. Whether it is the efficient refrigeration demand of food processing workshops for cold storage, the strict requirements for precise temperature control in pharmaceutical storage, or the stable operation of large-scale refrigeration systems in chemical enterprises, it can become a key part of optimizing refrigeration efficiency with its excellent performance and flexible adaptability. With its unique design and excellent performance, it not only ensures the stable operation of the refrigeration system, but also significantly reduces energy consumption and saves operating costs for enterprises. It is an ideal choice for the renovation and upgrading of various small and medium-sized cold storages and the construction of large industrial refrigeration systems.

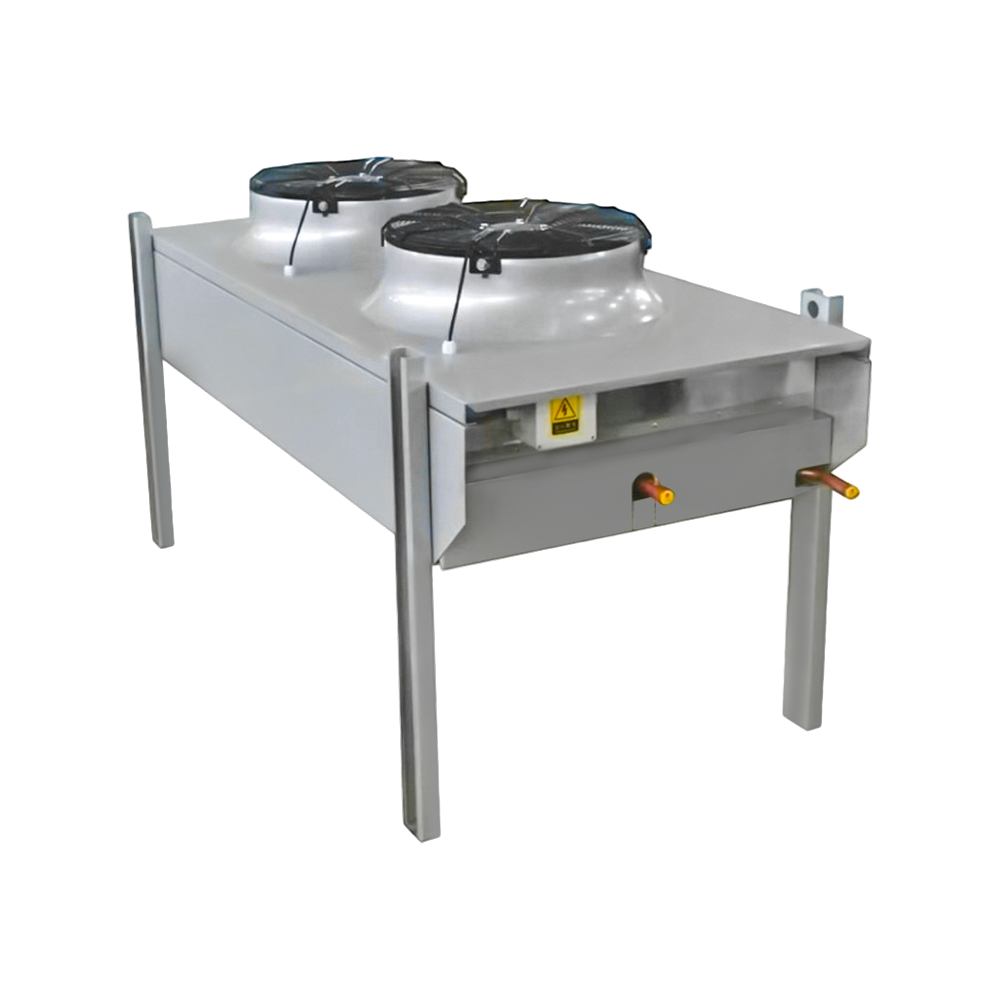

1. Innovative structure: A breakthrough vertical side-mounted design, giving it the characteristics of superimposed installation. Compared with traditional condensers, this design greatly reduces the area of the area. In an installation environment with tight space resources, it can make full use of vertical space and save users valuable site resources, especially for industrial factories and commercial places where every inch of land is valuable.

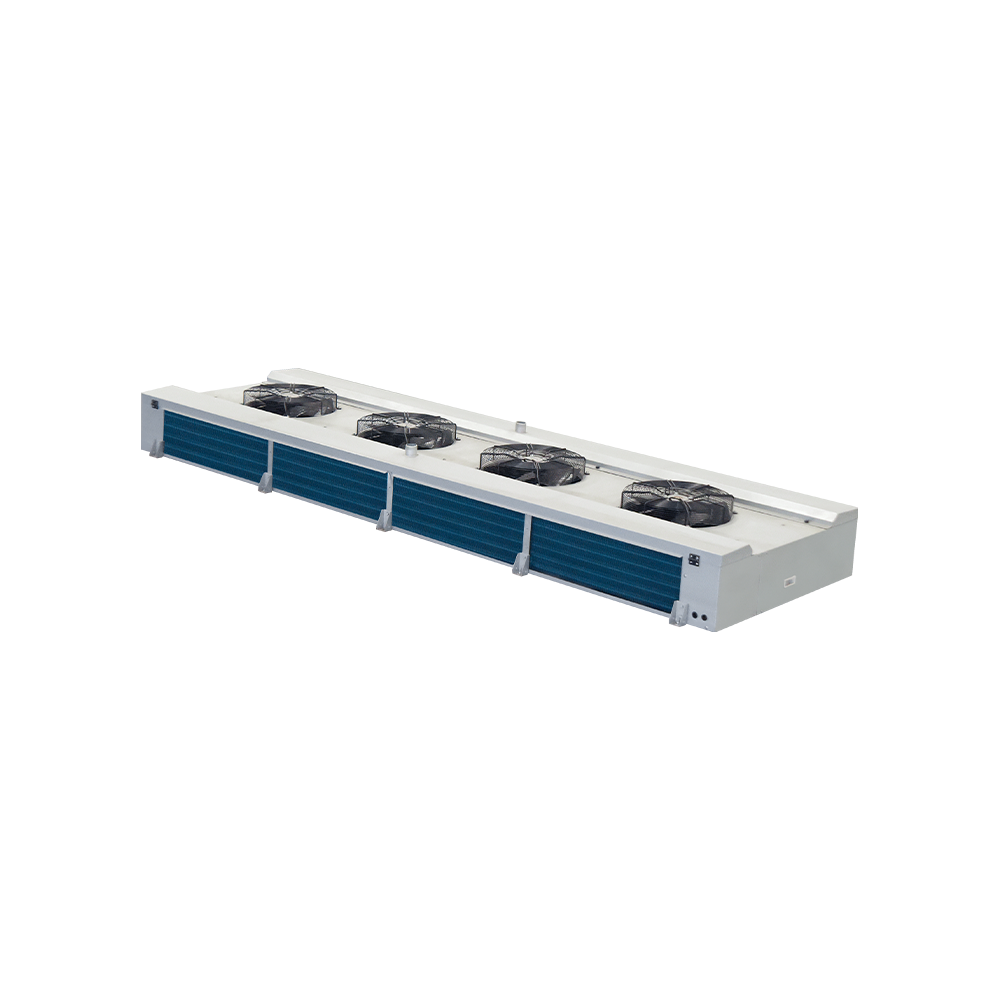

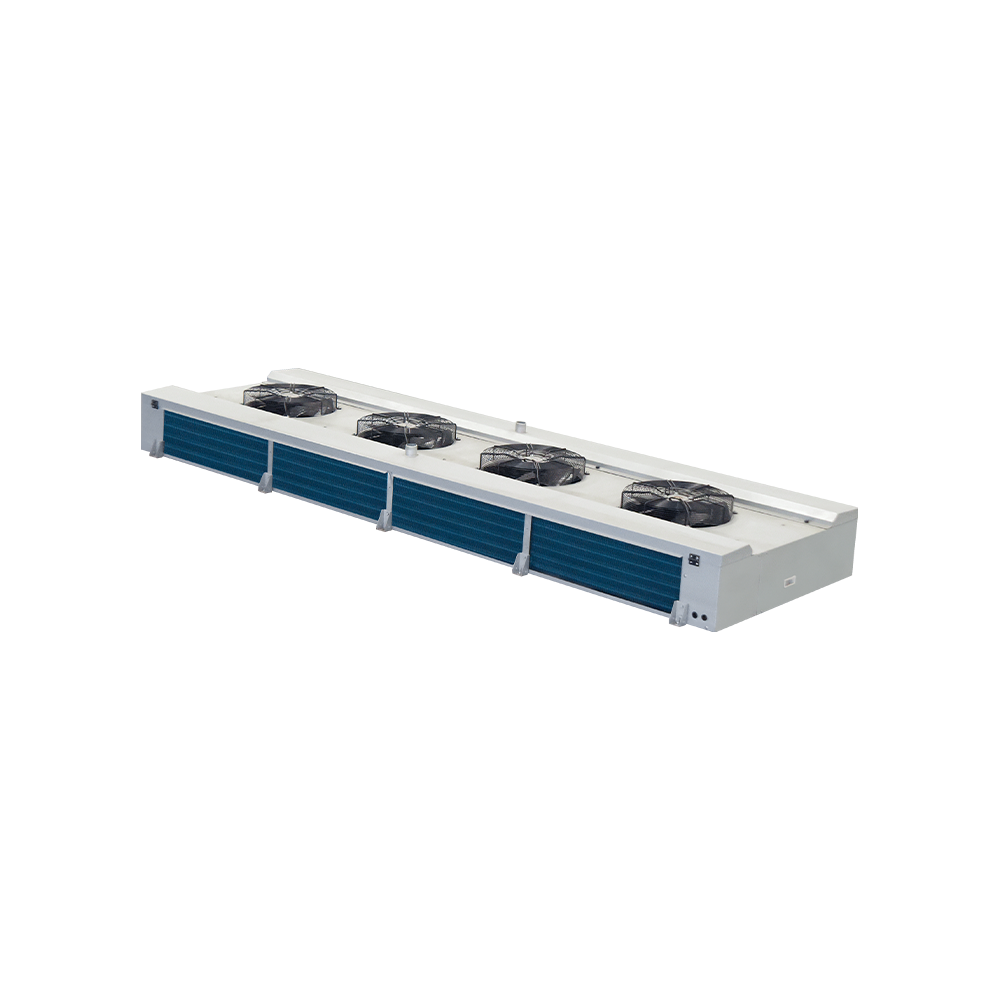

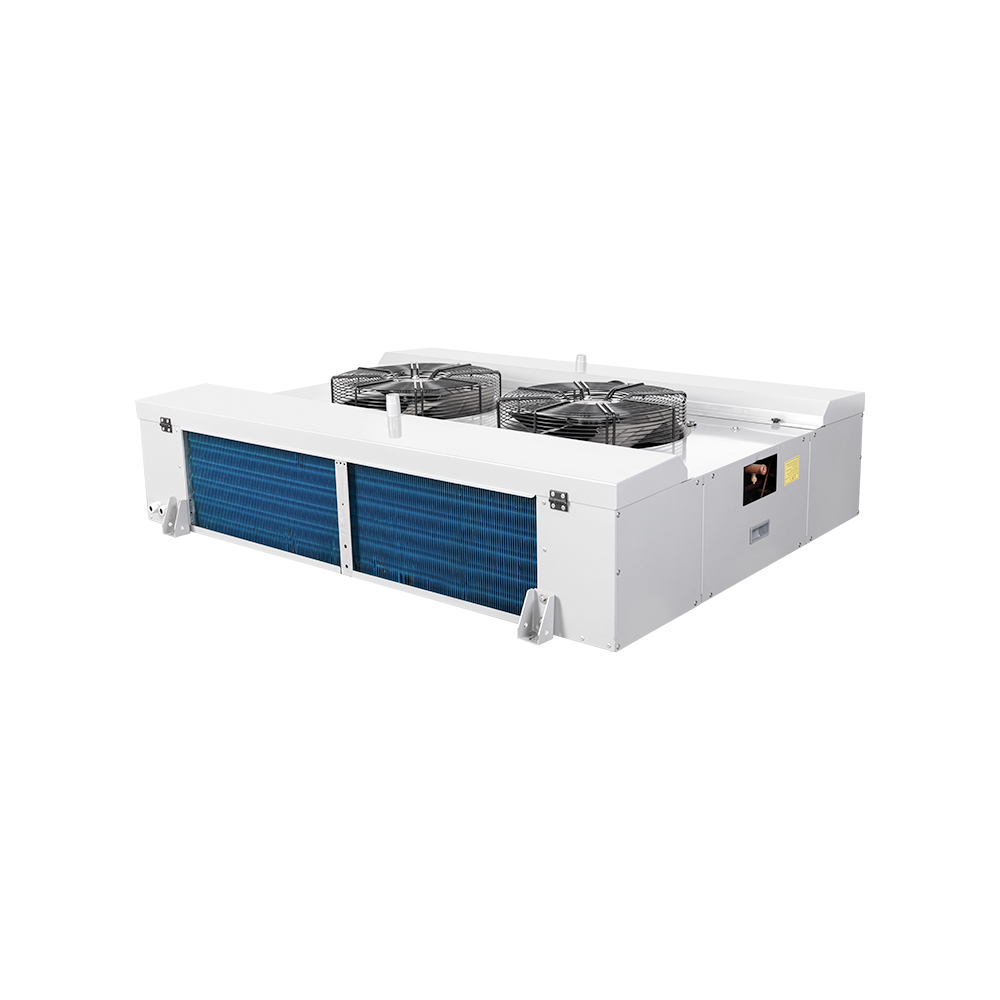

2. Appearance structure: The shell is made of high-quality galvanized steel plate and is treated with silver-gray RAL9006 plastic spraying process. It has durability and aesthetics, and can effectively resist damage to the equipment by damp and corrosive environments. The air ring adopts a high-wind ring design with an overall stretched large rounded corners, which not only makes the equipment look smoother and more atmospheric, but also optimizes the air conduction effect, ensuring that the airflow passes through the heat exchanger efficiently and improving the overall heat dissipation performance.

3. Core material: The end plate of the heat exchanger is made of aluminum plate, which can effectively protect the copper tube and prevent damage from copper tubes during transportation, installation and operation. At the same time, the lightweight characteristics of the aluminum plate reduce the overall weight of the equipment and facilitate handling and installation. The internal threaded copper pipe with a pipe diameter of φ9.5 is arranged in a triangle, which significantly increases the heat exchange area. Combined with the hydrophilic aluminum foil corrugated aluminum sheet, the 2.1mm piece-space design achieves efficient heat exchange, which improves the refrigeration efficiency while reducing energy consumption.

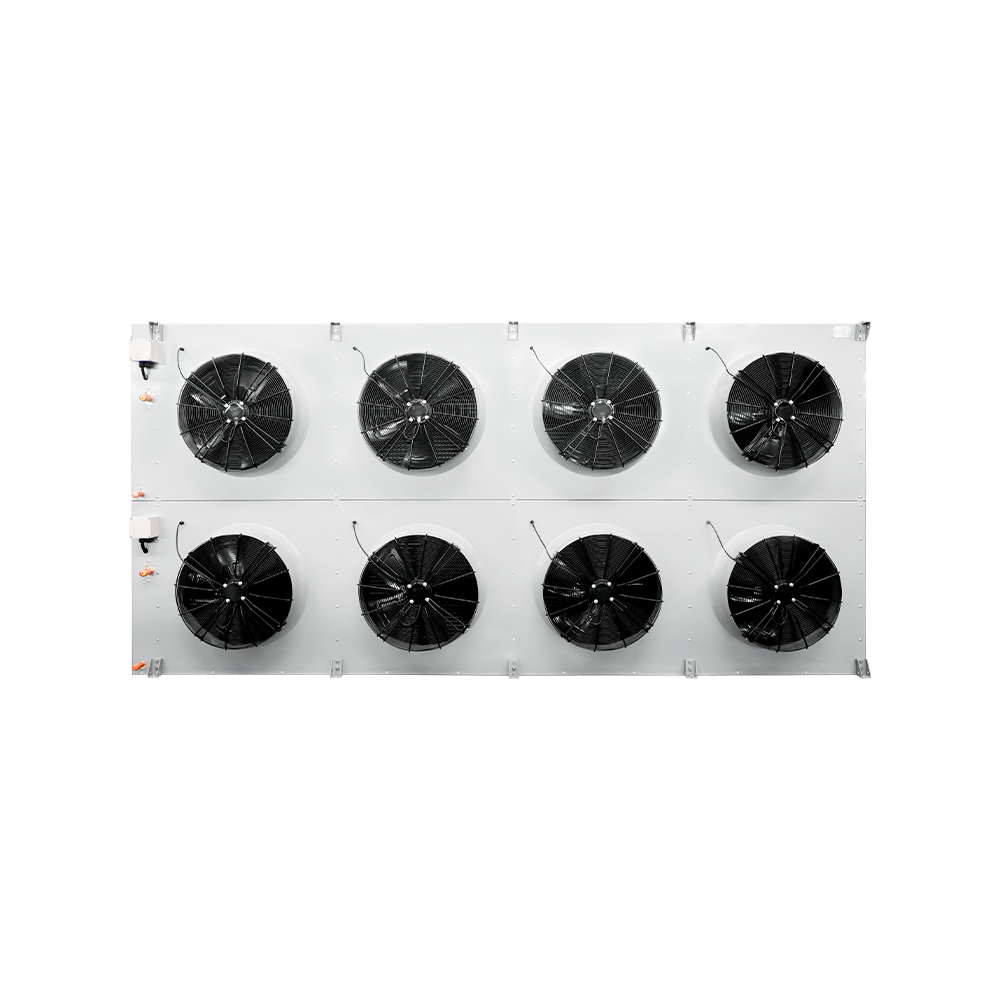

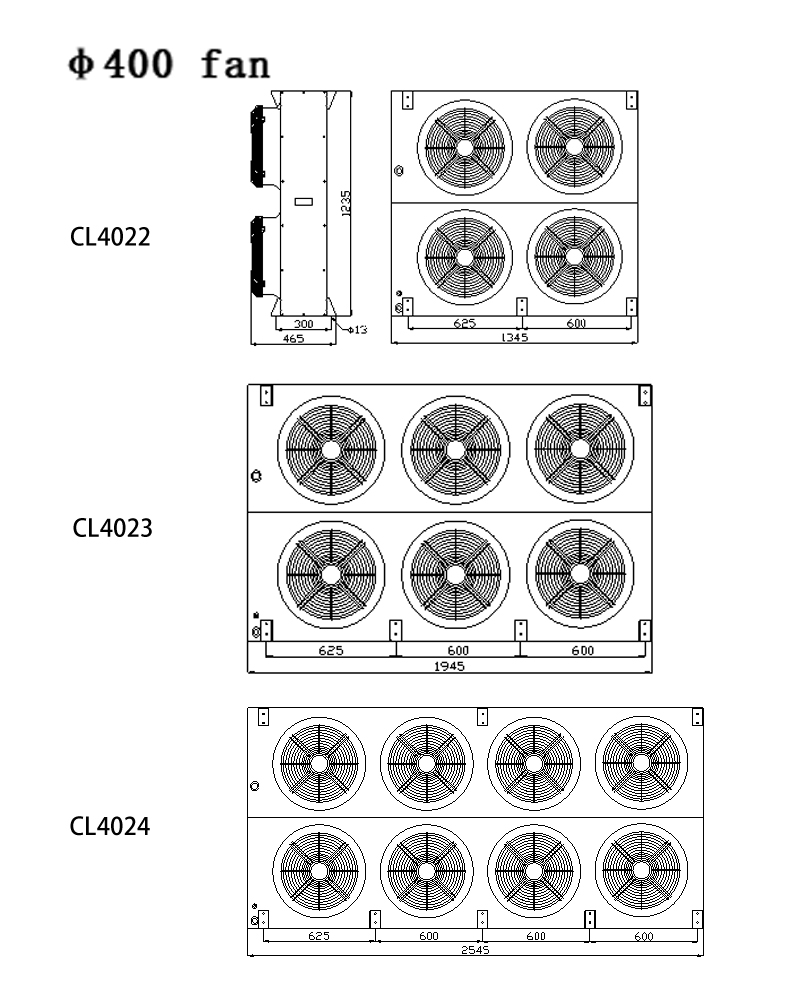

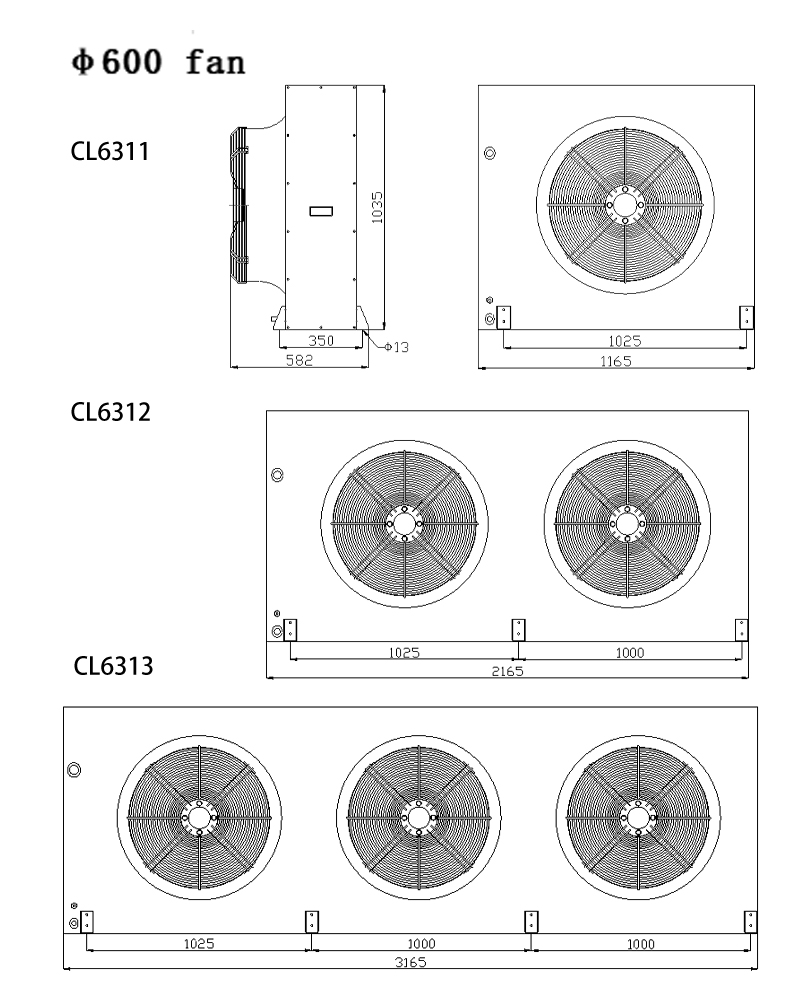

4. Fan configuration: Standard equipped with 3P/380V/50Hz power supply, providing external rotor fans of various specifications such as φ400, φ500 and φ630. Single exhaust fans can be configured with 1 - 3 pieces, dual exhaust fans can be configured with 4 - 6 - 8 pieces, and 4-pole motors are standard. The diversified fan combination methods can be flexibly adjusted according to different refrigeration needs, accurately match various working conditions, and ensure stable and efficient operation.

5. Performance guarantee: After rigorous 32bar pressure test, it ensures that the equipment is still safe and reliable in high-pressure environments; at the same time, it supports a variety of refrigerants such as R404A and R507A, is compatible with different refrigeration systems, providing users with a wide range of adaptation choices to fully meet diverse refrigeration needs.

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026