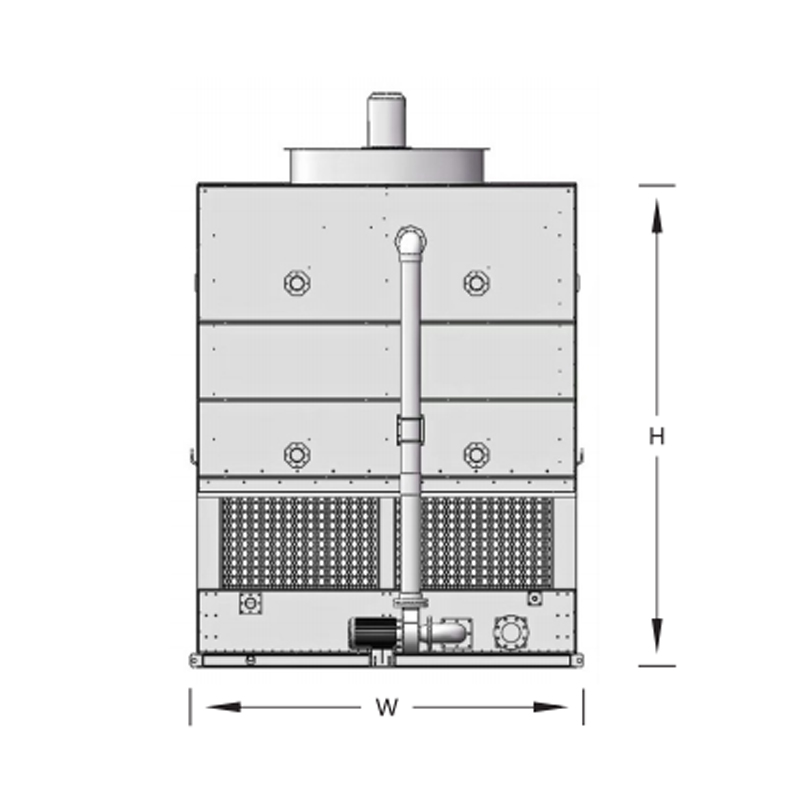

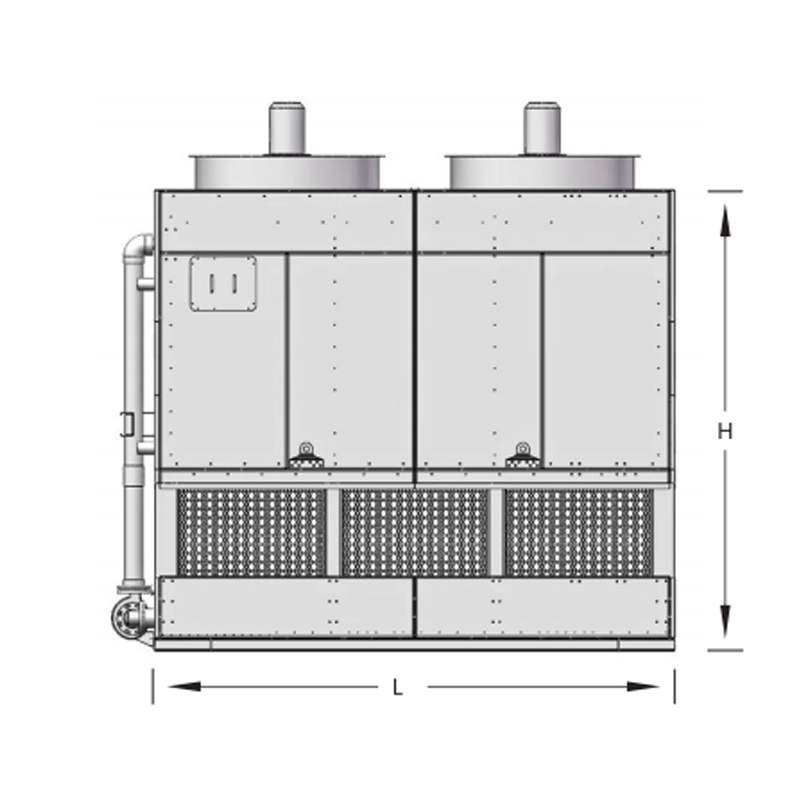

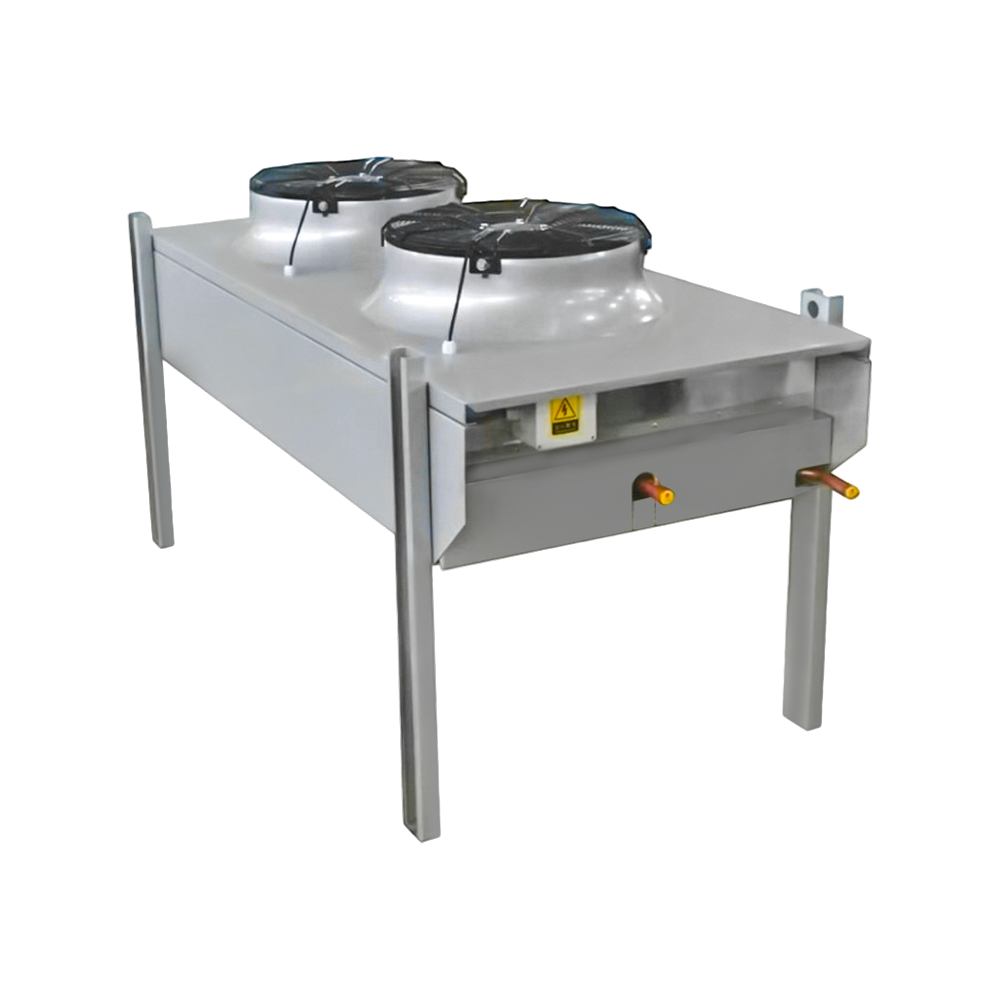

KDLN series evaporative condenser is an efficient water-saving condenser specially designed for medium and large refrigeration systems (cold storage, central air conditioning, industrial chiller units). Its design focuses on three major industrial pain points: extreme environmental adaptability (-30℃ severe cold to 50℃ high temperature), zero water consumption challenges (water scarce areas), and corrosive working conditions (chemical/coast). Its core uses dual-mode heat dissipation of "water evaporation heat absorption + air forced convection" to replace traditional water-cooled towers/air-cooled condensers to achieve an industrial-grade solution that saves energy by 30%~50% and water by 80%.

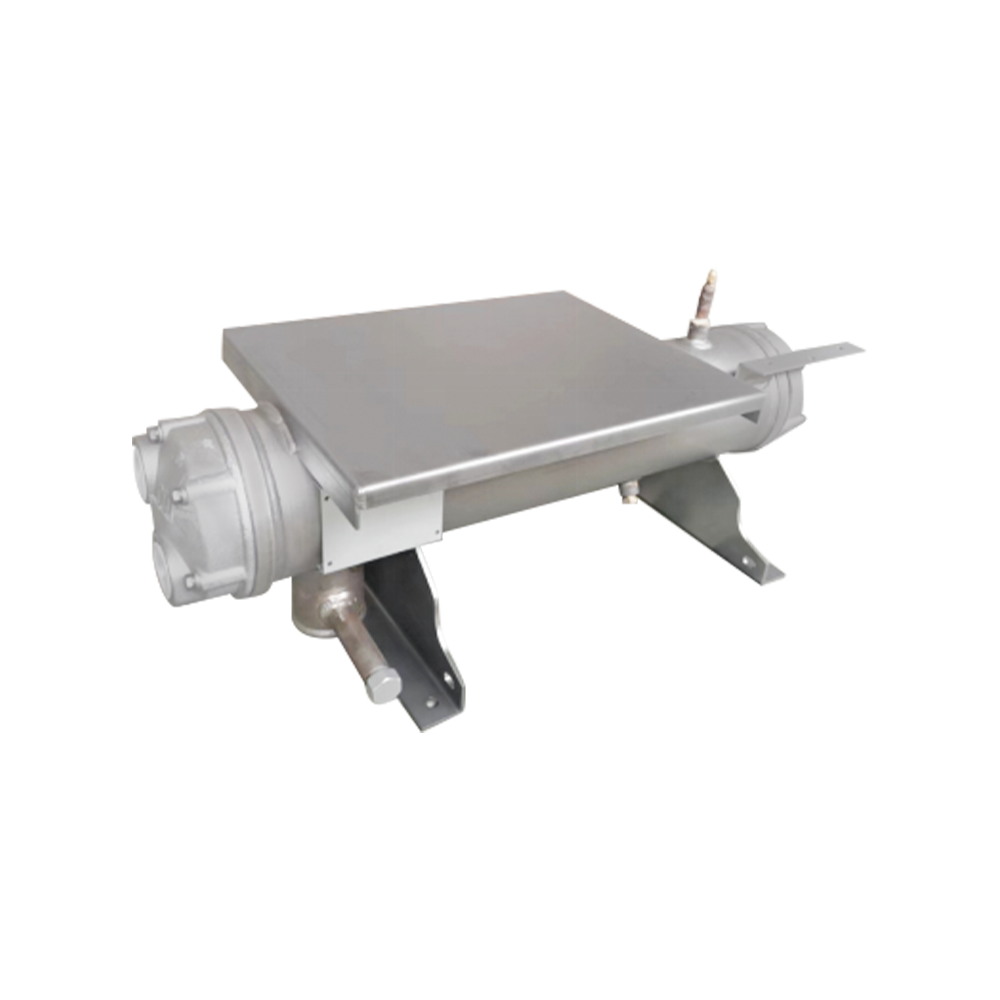

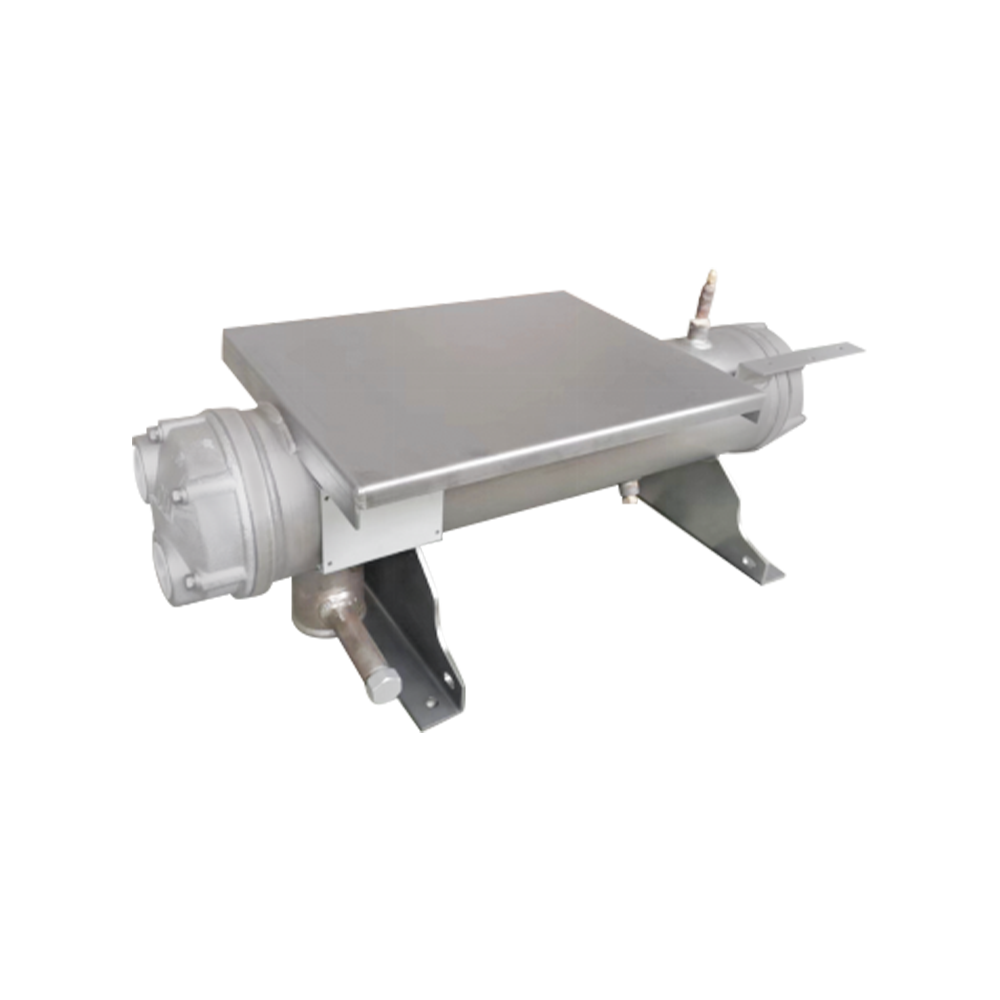

1. Elliptical tube countercurrent heat exchange system

20% additional heat exchange area (vs round tube): The equipment volume is reduced by 30% under the same cooling capacity

Downhill process: Refrigerant flow rate increases by 35% to avoid low temperature fluid accumulation

Materials available: 10# carbon steel (standard)/304 stainless steel (food)/316L (chemical)

2. Zero-drift water circulation system

Multidimensional PVC water collector: drift rate <0.001% (industry average 0.01%)

Stepped water tank: inclined self-flow design → sewage discharge efficiency ↑50%, preventing sedimentation and scaling

ABS umbrella nozzle: hole diameter ≥5mm to resist clogging, water film coverage >95%

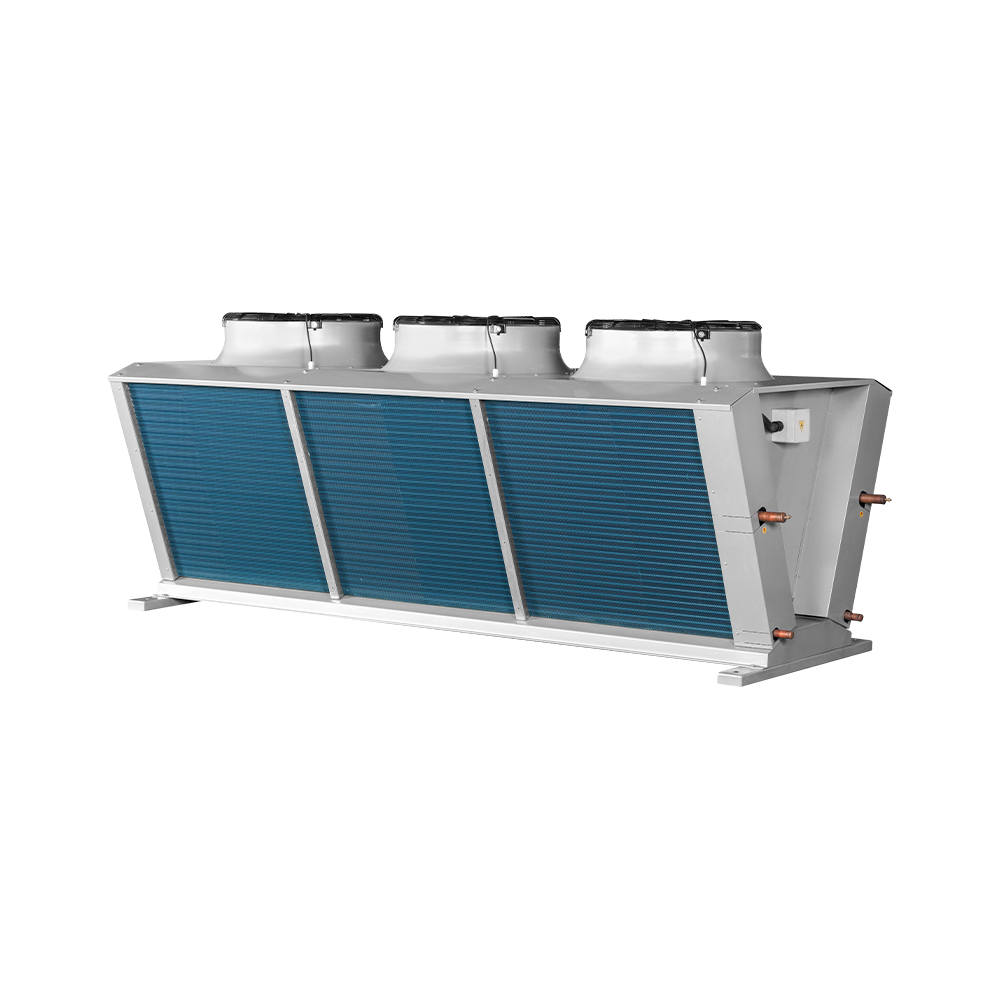

3. Anti-interference wind farm design

Independent air chamber module: eliminates air flow short circuit for multiple fans, heat exchange efficiency ↑18%

Honeycomb air inlet window: resistance ↓ 30% + sunshade and algae protection (PVC aging-resistant material)

Direct-connected fan: IP55 protective aluminum alloy blades → Transmission efficiency 98% (maintenance-free)

4. Intelligent water management

The variable frequency water pump adjusts the water volume according to the condensation pressure → Save 40% of water

Float valve + conductivity sensor → Automatic sewage discharge/water replenishment

5. Extreme environmental protection

Wind pressure resistance: Level 12 typhoon (150km/h) certified structure

Antifreeze: ethylene glycol cycle options (-30℃ operating conditions)

Anti-corrosion: All series can be selected for magnesium-plated aluminum-zinc plates/Z700 galvanized plates

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026