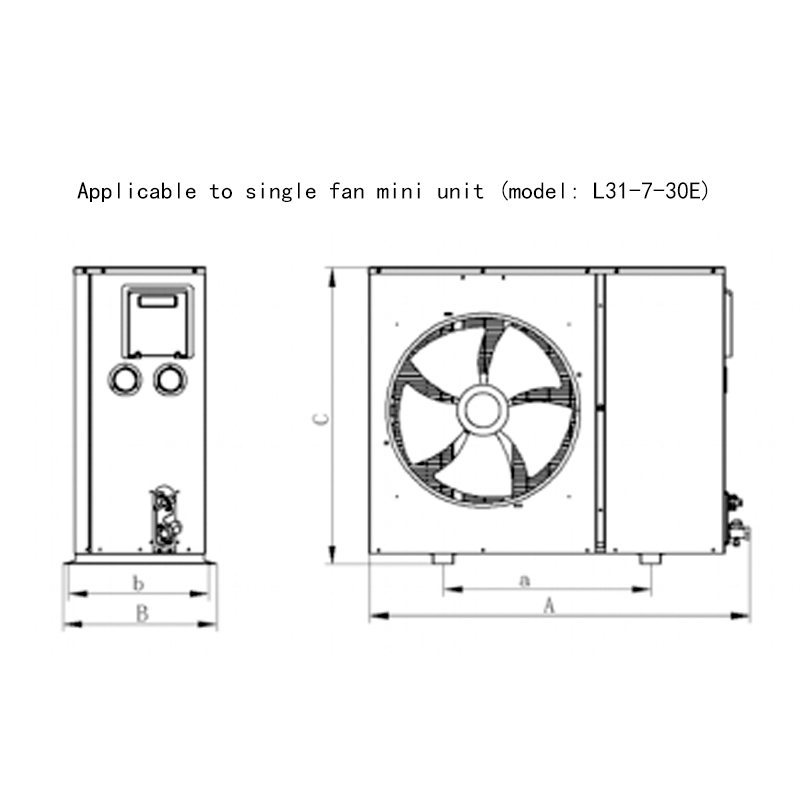

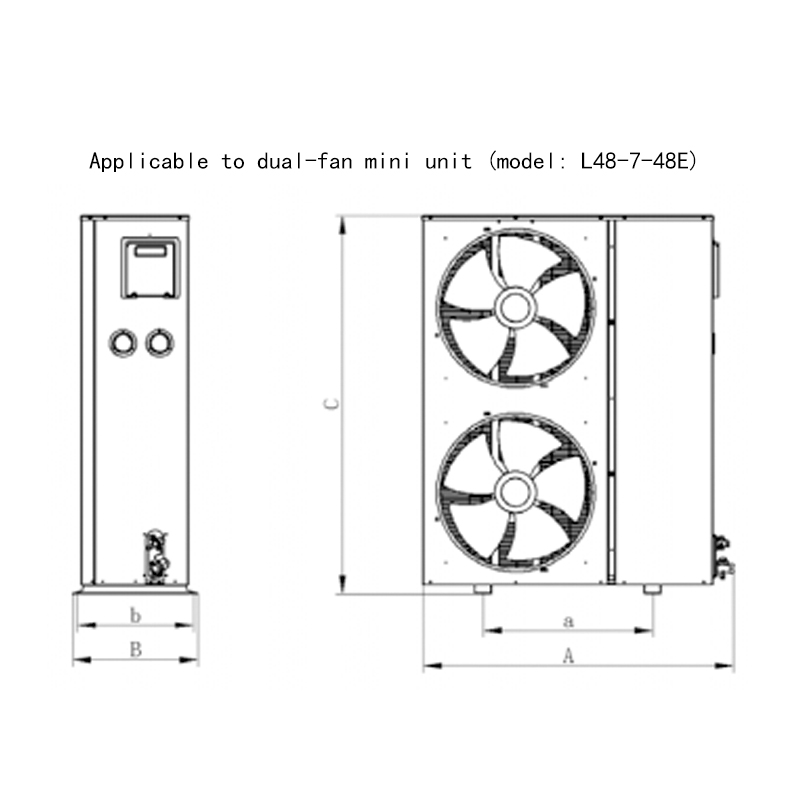

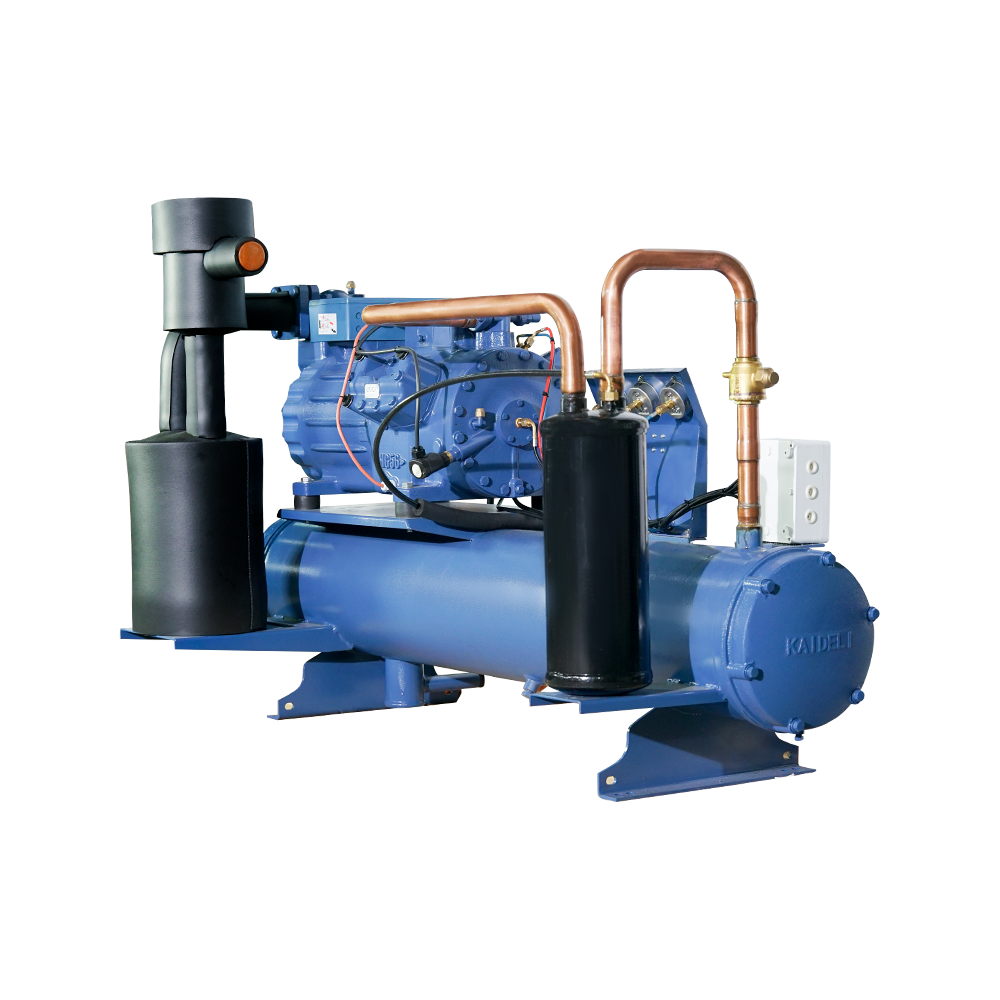

KL-E Series Condensing Unit is an industrial-grade compression condensing unit that integrates a scroll compressor and a high-efficiency air-cooled condenser. It adopts a simulation-optimized heat exchange design, is suitable for operation in a high-temperature environment of 45°C, has multiple safety protection mechanisms and low noise characteristics (≤65dB(A)), and is suitable for commercial cold chain systems.

Thermodynamic breakthrough: Italy Unilab customized flow channel design makes the condensation efficiency still 18% higher than the industry benchmark at 45℃

Mechanical redundancy protection: scroll compressor built-in oil cooling system + exhaust temperature real-time monitoring (accuracy ±1℃)

Structural anti-aging design: galvanized sheet spray box passed 10-year accelerated corrosion test (ASTM B117 standard)

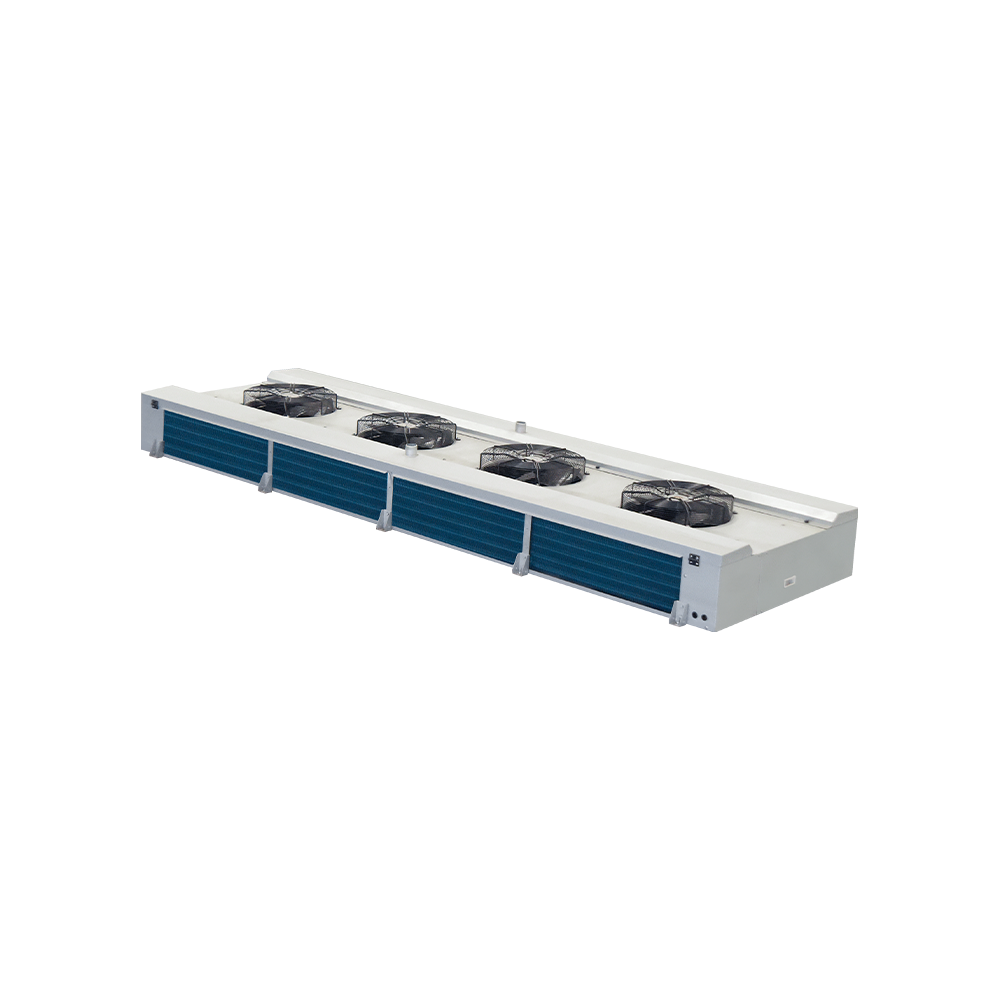

Intelligent wind system

▶ Glass fiber reinforced ABS fan blades (resistant to 120℃ high temperature) + 6-level high-efficiency inner rotor motor

▶ Spiral guide mesh cover achieves turbulent noise reduction, and the air volume increases by 18%

Industrial grade protection architecture

▶ Triple safety barrier: high and low pressure protection / exhaust overheat protection / motor overload protection

▶ New generation of galvanized sheet spray sheet metal box (salt spray test 1000h), corrosion resistance level IP54

▶ Internally pasted wave sound-absorbing cotton, operating noise ≤65dB(A)

English

English 中文简体

中文简体

09 Feb,2026

09 Feb,2026